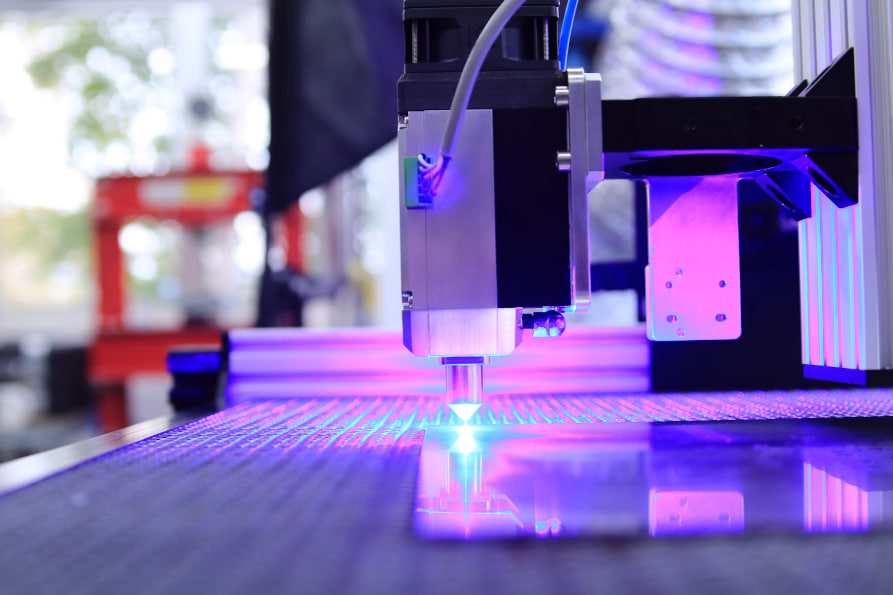

Introduction to CNC Tooling and Its Role in Manufacturing

CNC (Computer Numerical Control) tooling has redefined how tools and components are created in the manufacturing sector. By leveraging computer-controlled precision, these services have streamlined production, ensuring high efficiency and accuracy across various industries. Since their inception in the mid-20th century, CNC machines have evolved dramatically, shifting from rudimentary mechanical operations to highly sophisticated automated systems that form the backbone of contemporary manufacturing.

Key Advantages of CNC Tooling

One of the primary benefits of CNC tooling is its ability to produce components with exceptional accuracy. Unlike manual machining, which depends on human skill and consistency, CNC machines follow programmed instructions that ensure precision down to the smallest detail. This is especially critical in fields such as aerospace, automotive, and medical device manufacturing, where even minimal errors can have significant consequences.

Speed is another notable advantage. Automated machining processes drastically reduce production times, making it possible to meet tight deadlines and manage high-demand orders efficiently. Additionally, automation leads to lower labor costs, as fewer workers are needed to operate CNC systems compared to traditional machining setups.

Beyond efficiency and cost-effectiveness, CNC tooling enhances workplace safety. Since these machines handle complex cutting, drilling, and shaping tasks without direct human intervention, workers face reduced exposure to hazardous conditions and materials, minimizing the risk of injuries.

Why High-Quality CNC Tooling Matters

The quality of CNC tooling directly influences the final product’s durability and performance. Choosing high-grade materials and well-engineered tools ensures that manufactured components are resilient and long-lasting. Poor-quality tooling, on the other hand, can lead to defects, increased waste, and frequent rework, ultimately driving up production costs.

Additionally, well-maintained CNC tools contribute to operational efficiency. Over time, wear and tear can affect a machine’s precision, making routine maintenance and timely tool replacement essential for maintaining consistent output quality. Investing in premium CNC tooling minimizes downtime and prevents costly disruptions in production lines.

The Impact of CNC Tooling on Various Industries

Different industries rely on CNC machining to push the boundaries of innovation and efficiency. In the automotive sector, CNC technology is crucial for producing intricate engine components and body parts with unmatched accuracy. This has led to better-performing vehicles with improved fuel efficiency and enhanced safety features.

Similarly, the aerospace industry benefits from CNC precision when crafting components that must endure extreme conditions. The ability to fabricate intricate designs with tight tolerances ensures that aircraft parts meet the rigorous safety and performance standards required in aviation.

Even in consumer product manufacturing, CNC tooling enables mass production without sacrificing quality. Electronics, medical equipment, and industrial machinery all depend on CNC precision to maintain uniformity and performance across large product runs.

CNC Tooling and Mass Production Efficiency

For businesses engaged in high-volume production, CNC machining presents numerous advantages. One of its most impactful benefits is the ability to operate continuously with minimal downtime. Unlike manual methods that require frequent stops for adjustments, CNC systems execute pre-programmed operations with high repeatability, making them ideal for large-scale manufacturing.

Additionally, the automation inherent in CNC tooling reduces human error, ensuring that each component meets exact specifications. This not only improves product consistency but also reduces material waste and the need for costly rework. As a result, businesses can enhance their profitability while maintaining high production standards.

Enhancing Productivity Through CNC Technology

CNC tooling has transformed productivity in modern manufacturing by enabling multi-step machining processes to occur seamlessly. By performing several operations in a single setup, CNC machines eliminate unnecessary delays, allowing businesses to optimize production cycles and meet demanding schedules.

Another critical factor in efficiency improvement is the reduced setup time. CNC machines can store multiple programs, making it easy to switch between different product designs without requiring lengthy reconfigurations. This flexibility allows manufacturers to quickly adapt to changing market demands and customize their offerings with minimal downtime.

The Future of CNC Tooling in Manufacturing

The future of CNC machining is poised for significant advancements, driven by emerging technologies. One of the most promising developments is the integration of artificial intelligence (AI) and machine learning, which will enable real-time monitoring and optimization of machining processes. These innovations will lead to enhanced efficiency, predictive maintenance, and further reductions in operational costs.

Another key trend is the rise of hybrid manufacturing, where CNC machining is combined with additive manufacturing (3D printing). This approach enables manufacturers to create complex geometries that were previously unattainable with traditional methods, opening new possibilities in product design and material utilization.

Additionally, improvements in tooling materials and coatings, such as ceramic composites and diamond coatings, will enhance tool longevity and machining performance. These innovations will contribute to greater precision, reduced tool wear, and improved cost-effectiveness in manufacturing operations.