DN Solutions, a leading global manufacturer of precision CNC machine tools, has unveiled its latest entry-level multi-tasking mill-turn machine series at two major international exhibitions: IMTS in Chicago (September 9-14) and AMB in Stuttgart (September 10-14).

As the third-largest CNC machine tool manufacturer worldwide, DN Solutions showcased its new DNX 2100 series, which is designed to offer advanced multi-functional capabilities at a more accessible price point. This new range fills the gap between the company’s popular Puma 2100SY turning centers, equipped with a Y-axis and sub-spindle, and its higher-end SMX 2100S/ST mill-turn models. With the DNX series, manufacturers can access more integrated machining functions than those offered by the Puma models but at a lower cost than the SMX series.

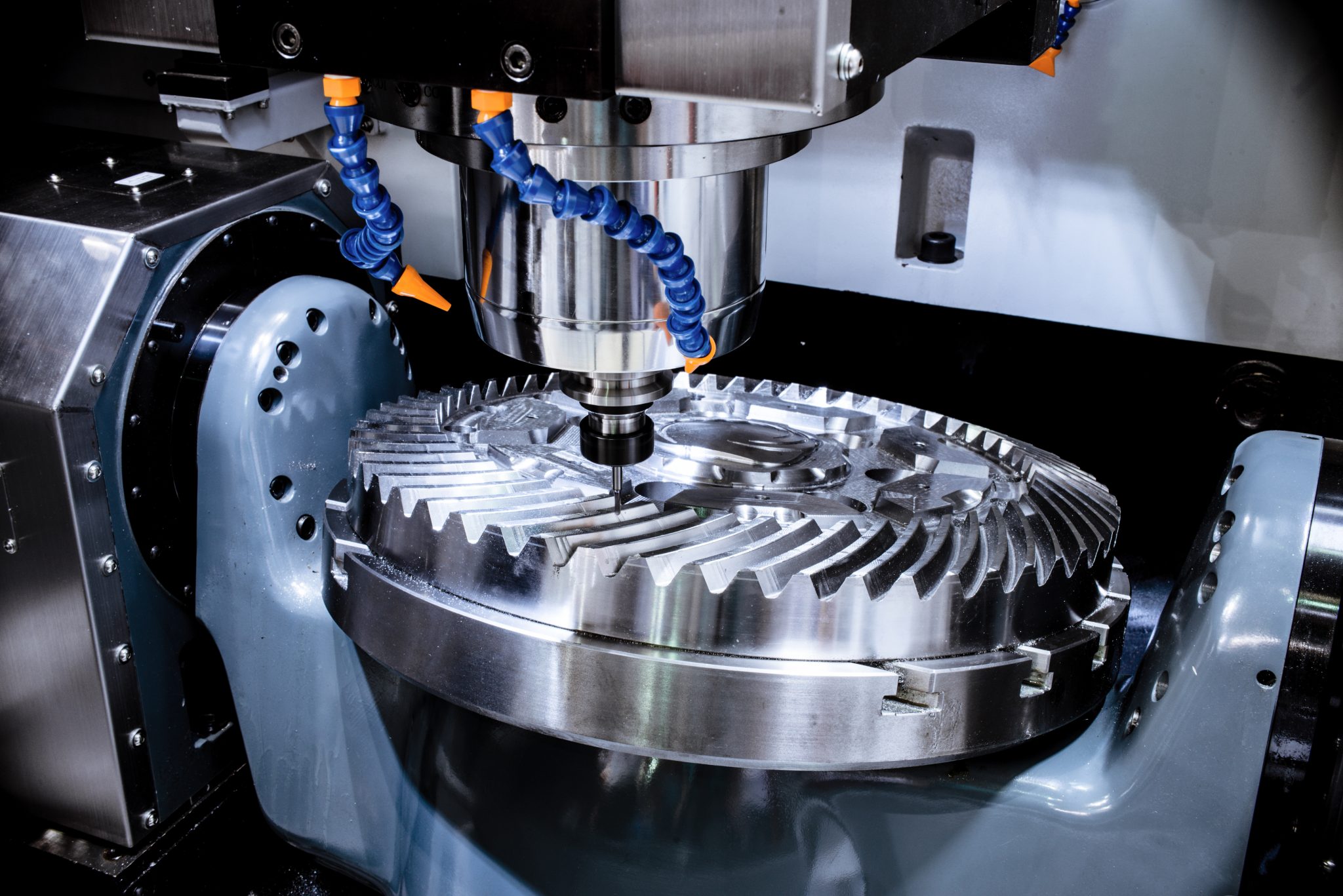

The DNX 2100 models, specifically the DNX 2100SB and DNX 2100S, come equipped with an 8-inch chuck, two built-in spindles (left and right), both capable of reaching 5,000 RPM, as well as a B-axis milling head with a speed of 12,000 RPM. The machine also features an automatic tool changer (ATC) with 40 tools as standard, with an option to upgrade to 60 tools, and it is controlled by the Fanuc 0i-TF Plus system.

This versatile machine series enables manufacturers to efficiently produce complex and high-precision components in a single setup. Compared to traditional Y-axis lathes with driven tools and a sub-spindle, the DNX 2100 offers greater productivity and flexibility, thanks to its larger tool capacity and multi-tasking capabilities.

With two model variants soon to be available, DN Solutions aims to provide component manufacturers with the tools to meet their diverse production needs, while maintaining cost-efficiency and high-quality performance.