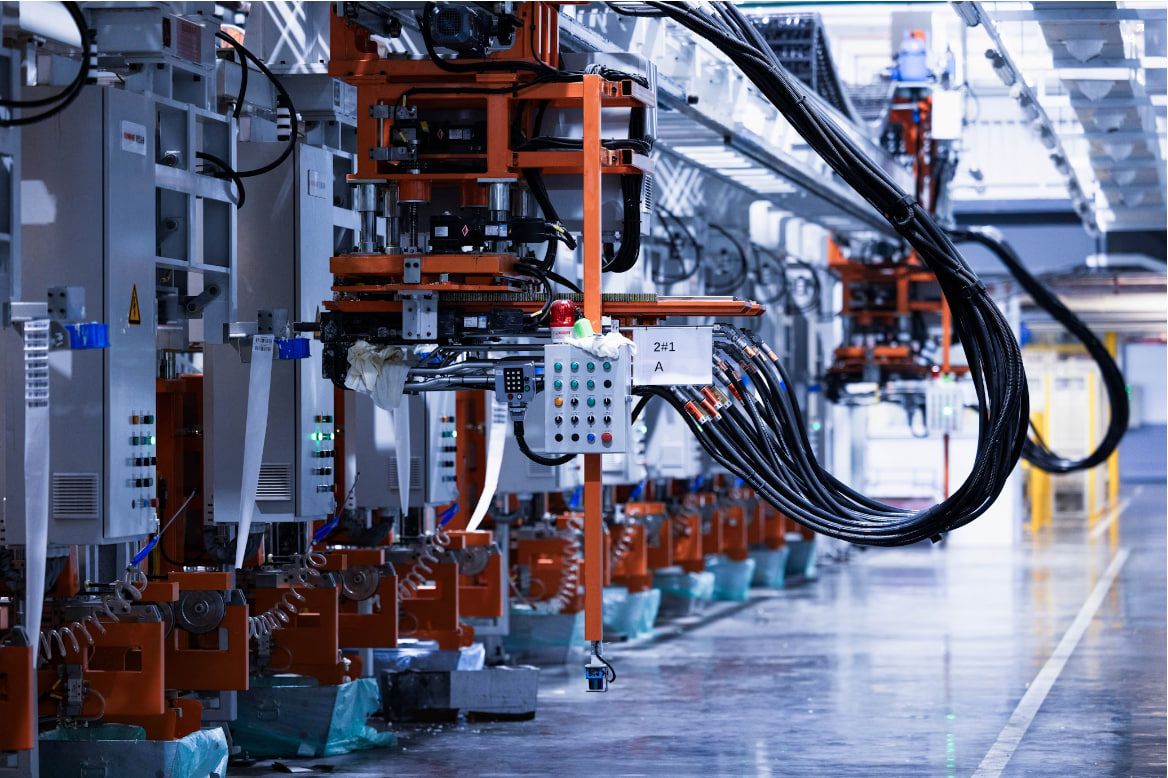

In modern precision manufacturing, efficiency depends not only on the CNC machines themselves but also on the supporting technologies that keep them accurate and versatile. Among these, rotary tables have emerged as a critical—yet often overlooked—component. Their ability to rotate, index, and precisely position workpieces enables advanced 4-axis and 5-axis operations, making them indispensable across industries such as aerospace, motorsport, medical device production, and toolmaking.

Why Rotary Tables Matter

If a rotary table fails, an entire machining center can grind to a halt. Original equipment manufacturer (OEM) repairs are often expensive and slow, leaving manufacturers with the challenge of either facing costly downtime or seeking third-party expertise. For UK workshops, reliable local repair, retrofit, and upgrade services have become a lifeline—especially for small and medium-sized enterprises working under capital constraints.

The CNCROTARY.COM Approach

One company stepping into this gap is CNCROTARY.COM, which focuses exclusively on rotary systems. Its services include repairing, upgrading, and building custom rotary units to suit specific production needs. The firm works with a wide portfolio of brands—Fibro, Peiseler, Haas, Nikken, Kessler, Cytec, Tsudakoma, Kitagawa, and many more—ensuring customers aren’t locked into costly OEM-only solutions.

For example, a recent refurbishment project documented by the company involved salvaging a high-value rotary system initially thought to be beyond repair. After a comprehensive rebuild—including mechanical overhauls, recalibration, new seals and bearings—the unit was restored to full functionality, providing the client with a cost-effective alternative to outright replacement.

Tailored Engineering for Competitive Advantage

The benefits of such services extend beyond cost savings. Many manufacturers are now prioritizing asset life extension, sustainability, and operational flexibility. Custom-built rotary tables, whether designed for multi-spindle setups, compact footprints, or non-standard bores, allow businesses to adapt equipment to evolving production demands without major reinvestment.

CNCROTARY.COM also supplies brand-new rotary tables—both standard and bespoke—engineered in close collaboration with clients. By matching specifications to the exact requirements of a production line, the company helps ensure seamless integration and minimal downtime.

Looking Ahead

With more than 40 years of engineering experience, CNCROTARY.COM positions itself as a bridge between standard off-the-shelf parts and fully tailored motion-control solutions. As CNC technology continues to advance and AI-driven automation expands into workshops, rotary integration will likely play an even bigger role in maintaining precision and uptime.

The question for UK manufacturers now is not just how to keep machines running, but how to do so strategically—maximizing productivity through smarter servicing, targeted retrofits, and partnerships with specialists who understand that every minute of downtime has a cost.