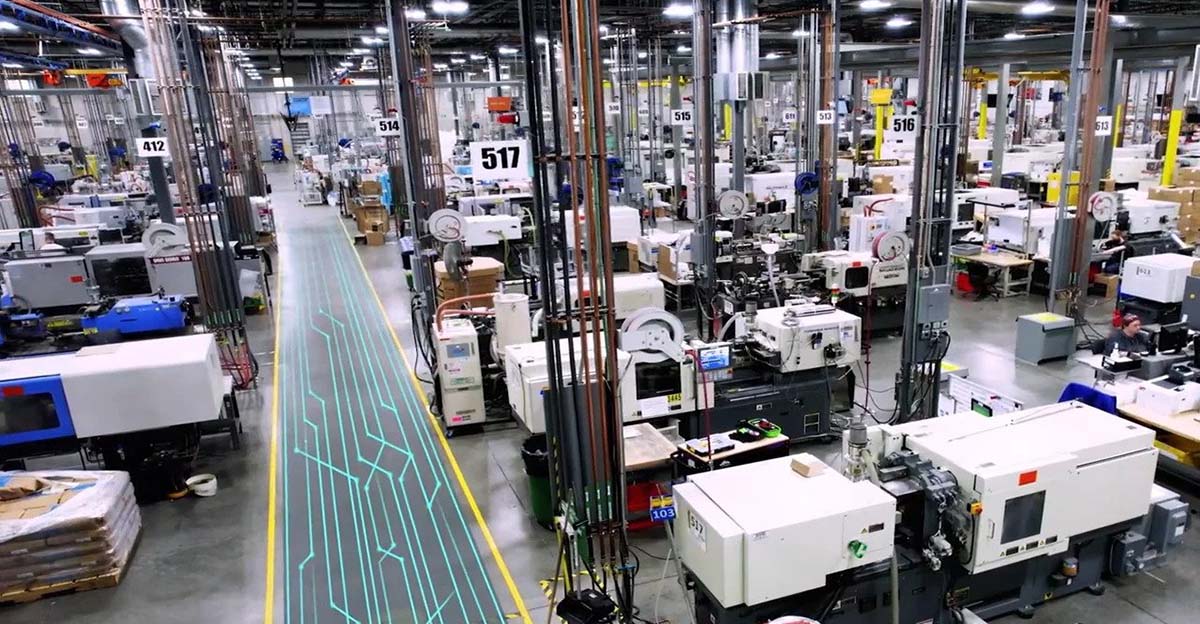

The recent conclusion of IME West, incorporating packaging, medical, and plastic manufacturing alongside the ATX West automation exhibition, marked a significant triumph, spotlighting a myriad of captivating technological showcases from numerous enterprises.

The closure of the ATX West exhibition at IME West in Anaheim heralds the forefront of innovation exploration, particularly in Control Automation, as numerous companies present novel advancements. For those who missed our initial day’s summary, a revisit is imperative to delve deeper into the offerings of these dynamic enterprises.

Mecademic: Pioneering Precision in Ultra-Small Robotics

In an era where technological facets tend to evolve towards grander, more robust, and faster iterations, the focus on applying specific technology to ultra-small industries necessitating utmost precision and tolerance is refreshing. Mecademic excels in this niche with its super-small articulated and SCARA robots tailored to deliver reliability across industries such as optics, semiconductors, electronics (PCB assembly), adhesives, and pharmaceutical applications. The pursuit of compact and precise industrial motion remains a paramount goal for many enterprises, and Mecademic’s commitment to achieving precision and repeatability at a remarkable order of 0.005 mm for a 6-axis industrial robot stands as a testament to its prowess.

Micropsi: Overcoming Variability with Vision-Driven Robotics

In the realm of robotics, variability within processes poses a significant challenge. Micropsi Industries specializes in addressing this challenge by employing stereo vision systems that enable robots to track intended objects or target locations even during approach, facilitating adjustments to ensure near-perfect final pick placements, even in scenarios where absolute position fixation proves unattainable. As industries progress, automation scenarios are bound to grow more intricate, underscoring the significance of companies like Micropsi Industries in achieving repeatable results crucial for automation success.

Vention: Empowering Machine Builders with Analytical Insights

Machine builders shoulder a formidable responsibility, tasked not only with designing and constructing custom work cells but also with ensuring sustained performance post-installation. Vention rises to this challenge by offering a comprehensive system of analytics and diagnostics accessible via a customer-specific dashboard, ranging from basic uptime/downtime metrics to live video monitoring of each robotic cell. Moreover, Vention leverages its proprietary machine building software, aptly named MachineBuilder, to facilitate collaborative design efforts, thereby minimizing costly miscommunication and empowering customers with active involvement in the design process.

Universal Robots: Collaborative Automation Redefined

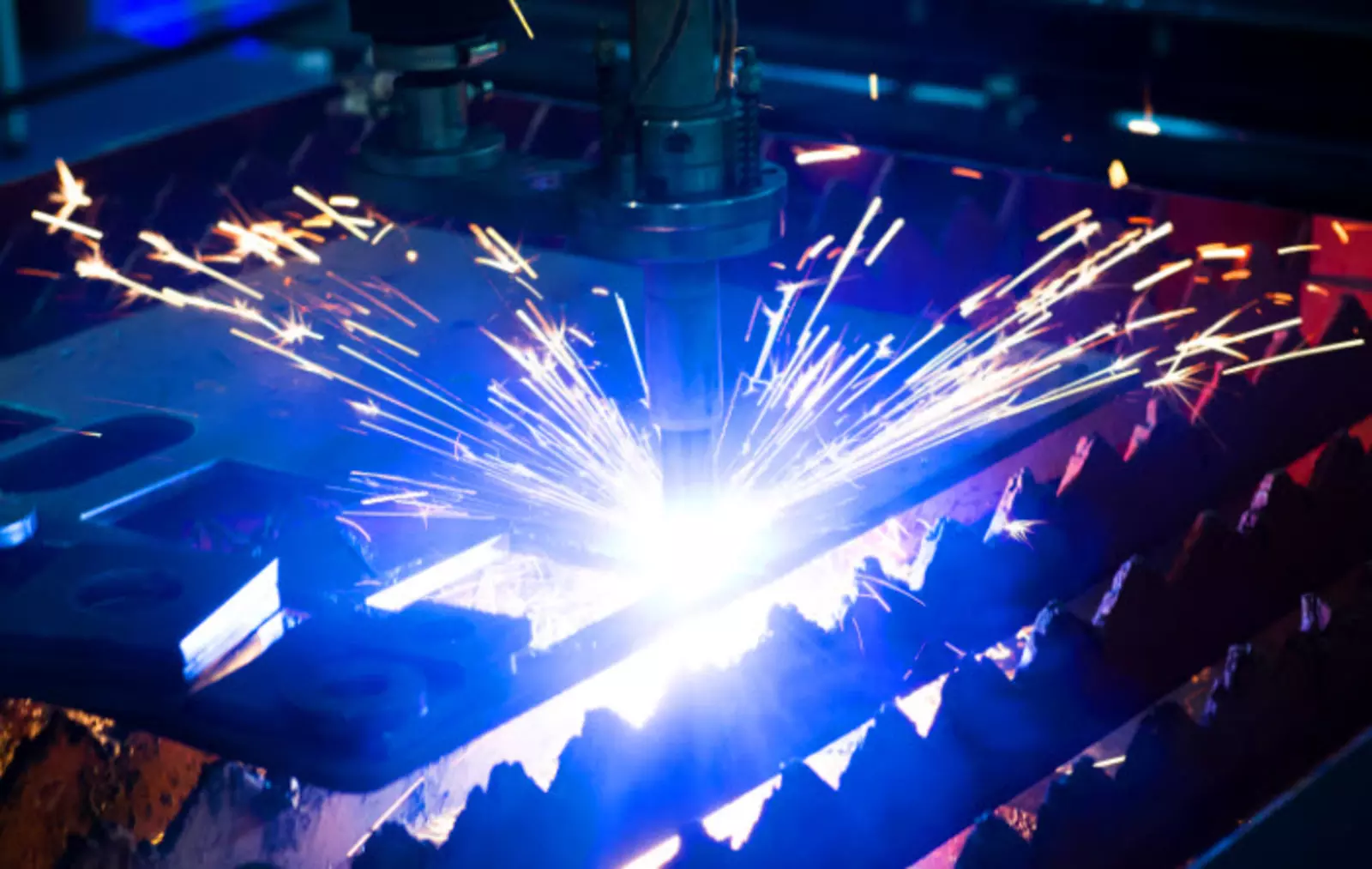

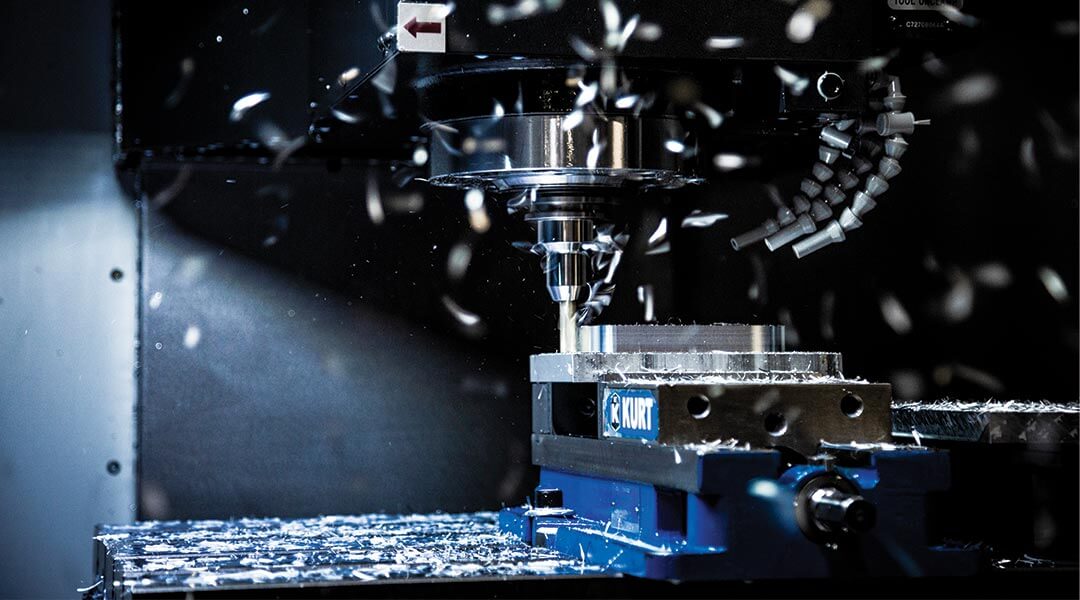

Universal Robots (UR) exemplifies collaborative automation by transcending mere robot manufacturing to establish an entire ecosystem, UR+, comprising integrators and manufacturers specializing in key industry verticals such as welding, palletizing, CNC operations, adhesives, and gripping. This ecosystem ensures that customers not only receive top-tier robots and peripheral products but also benefit from the expertise of seasoned professionals. At the UR booth, integration cells from VersaBuilt, Flexxbotics, and Kane Robotics showcased critical facets of the manufacturing process, ranging from CNC machine tending to grinding and deburring operations.

SMC USA: Elevating Control and Diagnostics in Air Supply Systems

As IME West centers on automation within manufacturing, design, healthcare, and medical industries, SMC USA showcased a range of devices integral to assembled products offering medical benefits. Noteworthy among these components is the advancement in control and diagnostic technologies for air supply, benefiting both medical and general industrial sectors. Management systems encompassing air regulation and filtration not only enhance energy conservation through prompt leak detection and mitigation but also leverage wireless technology to monitor branch air circuits, diagnose faulty lines, valves, and actuators, thereby prolonging the lifespan of air systems.