Computer numerical control (CNC) machining continues to evolve rapidly, driven by the growing demand for tighter tolerances, higher productivity, and improved reliability. At the heart of this progress are advanced rotary systems—specialized components designed to deliver smooth, stable, and highly accurate rotational motion. These solutions are playing a critical role in keeping CNC machining efficient, consistent, and adaptable to modern manufacturing challenges.

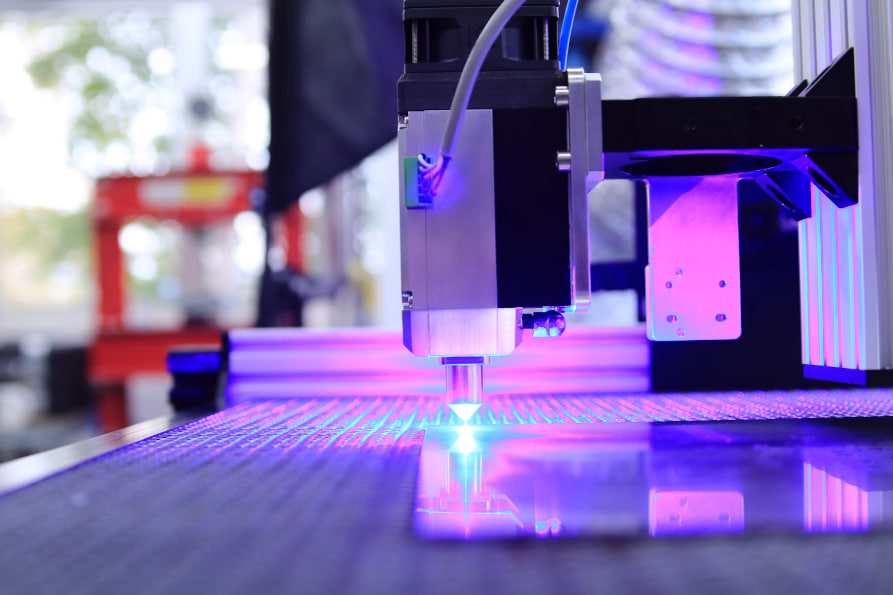

Enhanced Accuracy Through Precision Rotary Mechanisms

Modern rotary units, including rotary tables, indexers, and trunnion systems, significantly improve the accuracy of multi-axis machining. Their rigid construction and high-performance bearings minimize runout, vibration, and thermal deformation. As a result, tools maintain optimal positioning even at high speeds, enabling precise milling, drilling, and contouring operations. This precision is essential for industries such as aerospace, medical device manufacturing, and mold-making, where even minor deviations can lead to part rejection.

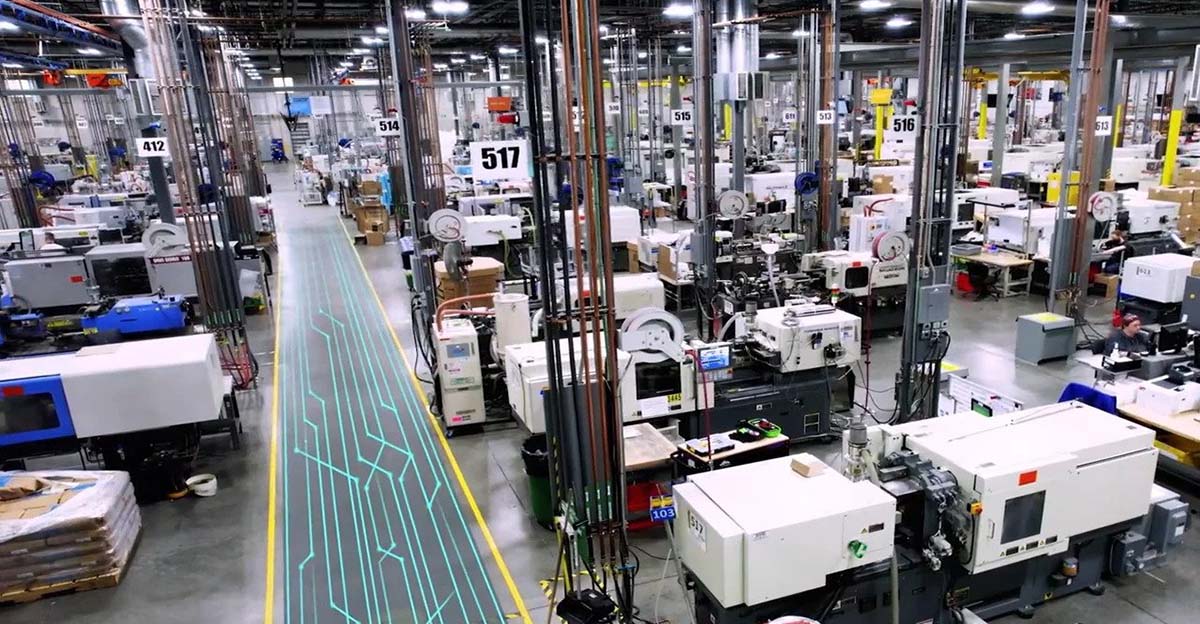

Improved Productivity and Workflow Efficiency

Advanced rotary systems allow CNC machines to complete multiple operations in a single setup. By adding 4th or 5th-axis functionality, they reduce the need for manual repositioning and fixture changes—common sources of downtime and human error. With faster indexing speeds and high torque output, these systems support heavy-duty cutting environments while maintaining machining stability. Manufacturers benefit from shorter cycle times, improved workflow consistency, and increased part throughput.

Durability and Stability in Demanding Environments

Specialized rotary solutions are engineered to withstand harsh machining conditions. Sealed housings, high-load bearings, and advanced lubrication systems protect internal components from coolant, chips, and heat. This durability ensures long service life with minimal maintenance. For shops operating under continuous production schedules, the reliability of rotary systems directly influences machine uptime and overall operational performance.

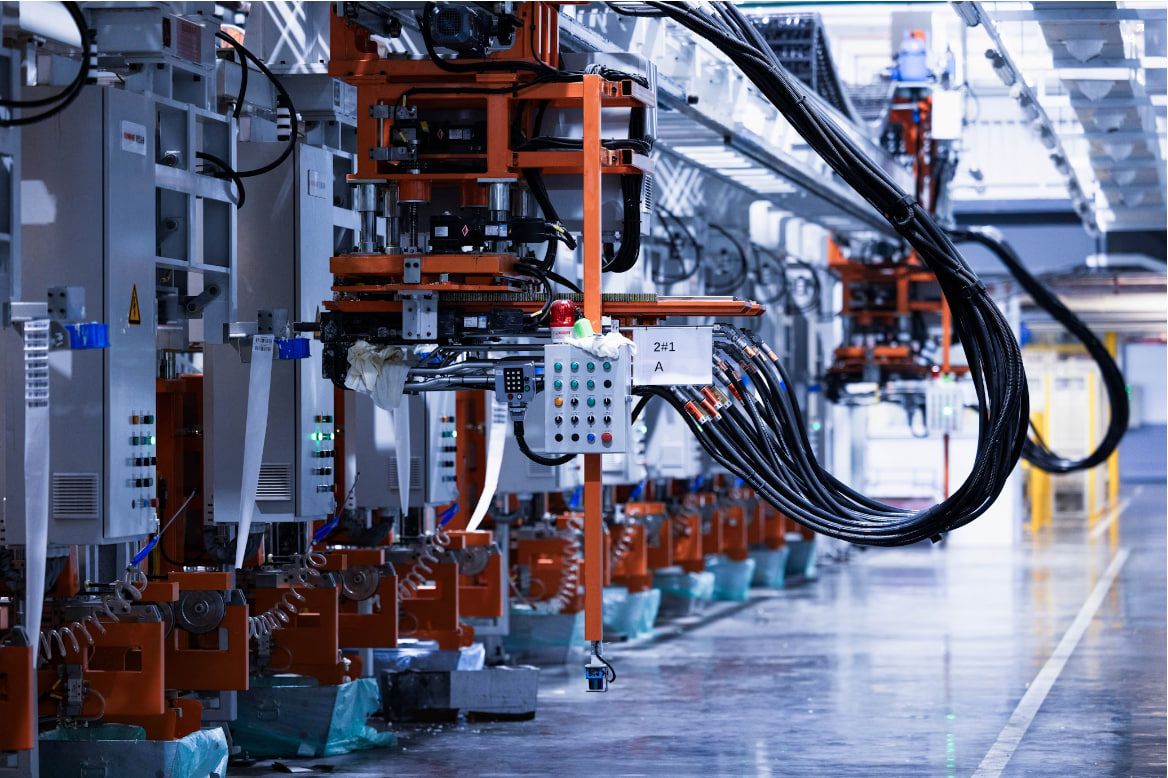

Adaptation for Complex and Hybrid Manufacturing

As hybrid machining methods—such as combining additive manufacturing with subtractive CNC—gain popularity, rotary units are becoming even more important. Their ability to precisely orient parts enables complex geometries, multi-face machining, and seamless transitions between processes. Additionally, modern rotary systems are increasingly integrated with digital control platforms, offering real-time monitoring, automated calibration, and adaptive motion control.

Advanced rotary solutions are essential for the continued evolution of CNC machining. By enhancing accuracy, improving productivity, and providing long-term stability, they help manufacturers stay competitive in a market that demands precision and efficiency. As industries move toward more complex components and multi-process production environments, the role of high-performance rotary systems will only continue to grow.