The intricate world of modern-day manufacturing often poses the task of discerning the workings of various machinery and techniques. Recognizing the disparities between CNC milling and CNC turning is instrumental for machinists, ensuring optimal utilization of resources. During the design phase, it provides CAD and CAM professionals the clarity to design components that favor one specific machine, optimizing the production workflow.

Milling and turning, while somewhat similar, employ unique strategies to shape materials. They are both methods that subtract material. Their utility spans from petite to vast components and a diverse range of materials. Their distinctions, however, guide their application suitability.

This discourse delves into the rudiments of CNC turning and CNC milling, their utilities, and their primary variances.

CNC Milling – A Closer Look What’s CNC Milling About? Through bespoke, predominantly digital design aids, CNC milling deploys an array of spinning cutters to carve material off a piece. What emerges is a tailored component, steered by a G-code CNC schema, replicable for uniform product batches.

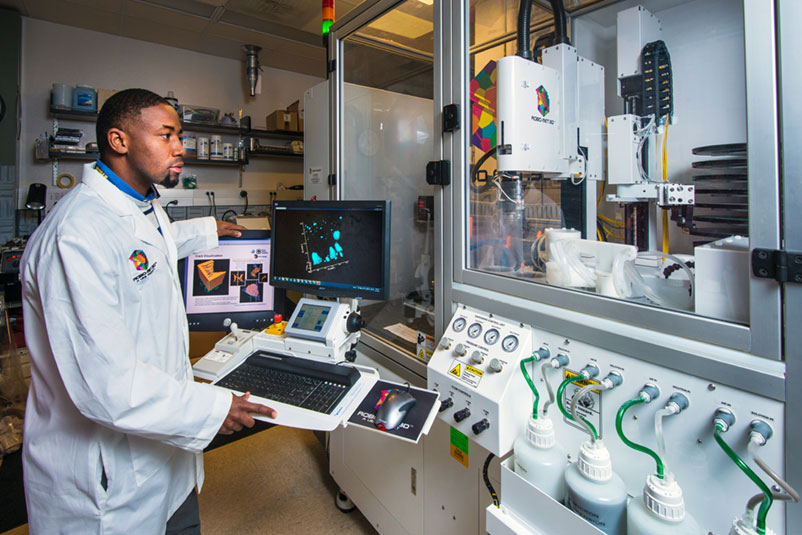

The Scope of CNC Milling in Production: CNC milling caters to both mammoth and modest production scales. From robust industrial arenas to nimble workshops or even sophisticated labs, milling is versatile. While they cater to a plethora of materials, certain mills have specific areas of expertise, such as metal versus wood applications.

Uniqueness of CNC Milling: Primarily, milling apparatus anchors the material on a platform. The machine’s layout might allow this platform to traverse along the X, Y, or Z trajectories, with the material itself being static. The milling tools, usually aligned horizontally or vertically, revolve to carve out the material.

Such machines can perforate the material or retrace their paths over it, simulating a grinding mechanism.

CNC Turning – A Deeper Dive What Exactly is CNC Turning? Turning is articulated by clasping material bars in a mechanism, spinning them, and introducing a cutter to shape it. CNC turning integrates digital command sequences for this shaping process.

Modern Manufacturing & CNC Turning: CNC turning stands out when crafting irregular or cylindrical components. It’s also adept at operations that maintain the original structure – like boring or threading. It’s a method behind crafting components ranging from substantial rods to specific screws.

Distinct Features of CNC Turning: In essence, turning apparatus, like a CNC lathe, spin the component whilst the cutter remains stationary. This dynamic renders possibilities that would be challenging for conventional milling machines. The tools are distinctly mounted, providing stability due to the rotation between the principal and secondary ends. Such stability allows for diverse cutting techniques and finishes.

Although turning centers can accommodate active cutters, these are more typically seen on milling machines.

Contrasting CNC Milling and CNC Turning: CNC milling employs revolving cutters and linear movement to carve the material’s face. In contrast, CNC turning offers precision in carving holes and configurations with exact dimensions.

Turning, in layman terms, mirrors traditional lathe operations but spins the main unit instead. The machinery’s movement is pivotal, typically powered by a motor, allowing full-circle operation without interruptions.

Both methodologies are governed by CNC commands, defining every move in the production sequence, ensuring precision. This precision and automation imply minimal manual intervention, reserving human input for oversight and loading tasks.

Choosing Between CNC Milling and Turning: When sculpting a piece, CNC milling shines for tasks like surface alterations and designs demanding symmetry or angles. Depending on the orientation of the cutting tool, mills can be horizontal or vertical, each with distinct attributes. A sturdy vertical mill can tackle diverse tasks with finesse. In contrast, horizontal mills, or the robust vertical variants, are tailored for extensive production cycles, evident in almost every contemporary production house.

CNC turning, conversely, is the go-to for prototype designs or lesser volume outputs. It thrives when dealing with irregular or cylindrical designs and can scale up for bulk production of specific items, like fasteners.

In essence, while both machines are the linchpins of CNC production, they differ in their core operation. Turning machines spin the component, whereas milling devices rotate around the cutting instrument. Mastery over either, or both, enables machinists to deliver components with unparalleled precision.