Eplan, a leading provider of software and service solutions, has recently rolled out an update to its data portal, enriching it with an extensive array of components from various manufacturers.

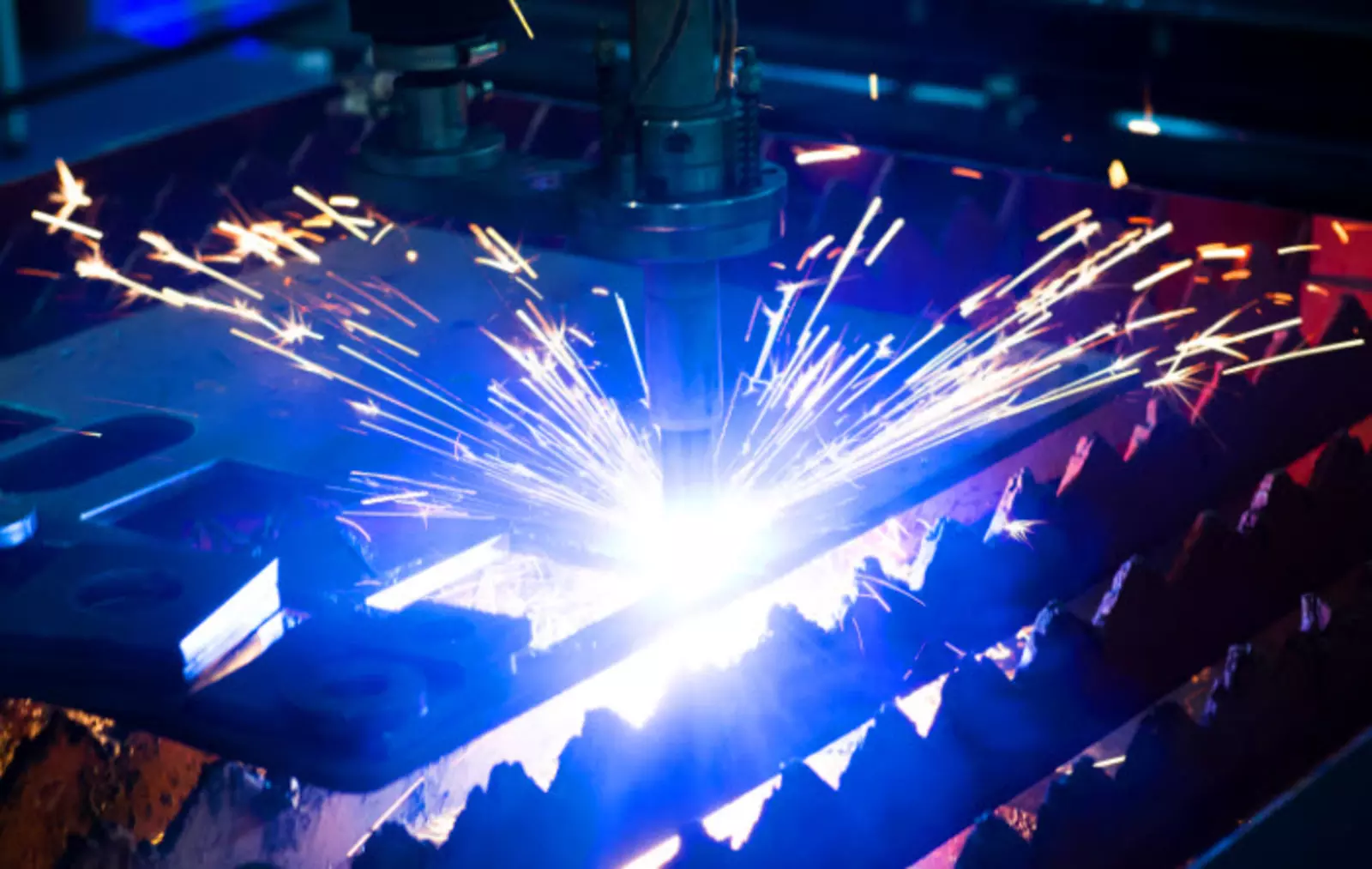

Digitizing Electrical Design Electrical design entails illustrating the interconnection of diverse electrical components in a visually comprehensible manner, facilitating technicians in constructing equipment on the workshop floor. Eplan specializes in designing software tailored specifically for electrical design, empowering designers to create digital blueprints for technicians. In its latest software update, Eplan has introduced enhancements, incorporating new manufacturers and augmenting data related to existing components, thereby broadening the utility of the software.

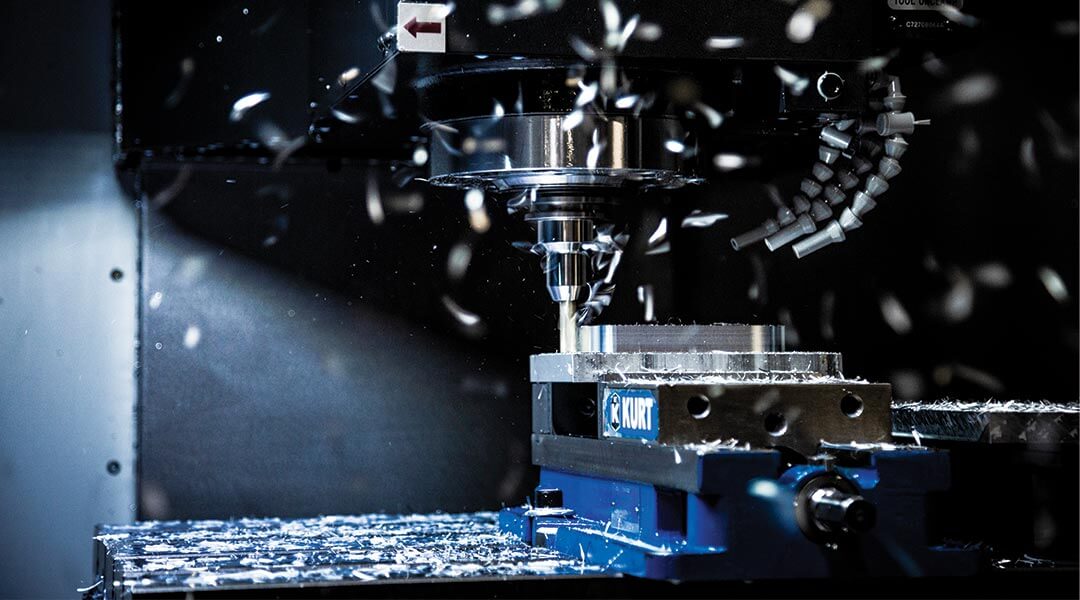

Eplan Design Solutions The Eplan platform encompasses a suite of applications designed for crafting hydraulic, pneumatic, and electrical systems, as well as for preplanning and 3D modeling of electrical cabinets. Unlike standalone CAD software, Eplan collaborates with top-tier manufacturers, enabling designers to select components from an extensive library. These components can be seamlessly integrated into designs, with each component’s metadata stored within the project. This streamlined workflow minimizes the time designers spend searching for component manuals or wiring diagrams.

Moreover, Eplan offers compatibility with various software systems, including enterprise resource planning (ERP), product lifecycle management (PLM), and product data management (PDM) systems. By establishing connections and sharing data with business management systems, designers and engineers can monitor their designs throughout the manufacturing process until final customer acceptance.

Eplan transcends its role as merely an electrical CAD software—its offerings extend to designing hydraulic and pneumatic systems. Similar to Eplan Electrical, users of the Eplan Fluid application can leverage the data portal, facilitating the rapid and accurate creation of schematics through a user-friendly drag-and-drop interface.

Embracing Standardization and Documentation Standardizing designs proves to be a cost-effective measure for equipment builders. Eplan supports standardization and template-based approaches, as well as manual creation of electrical schematics. Through its partnerships with manufacturers and incorporation of metadata in projects, Eplan ensures that project documentation is generated concurrently with the design process. Automatic completion of bill of materials, inclusive of part numbers and quantities, streamlines the documentation process.

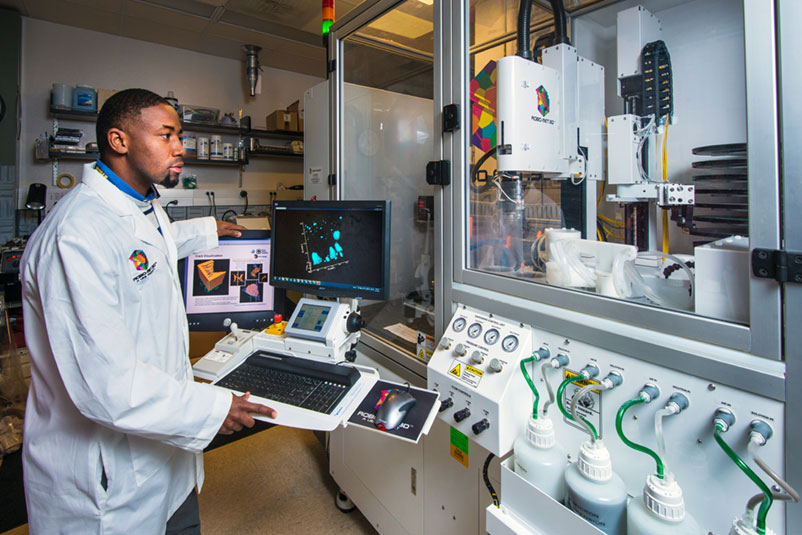

Eplan Data Portal Update Eplan’s data portal continually expands its catalog of available components by leveraging actual component data from industry partners. In the latest update, Eplan has integrated two new manufacturers, Federal Signal and Gefran, offering data for an array of components such as lights, signal devices, switches and pushbuttons, amplifiers, controllers, fluid power accessories, contactors, PLCs, and protection devices.

Furthermore, Eplan diligently updates its library to reflect changes in component catalogs, including updates and obsolescence. The January update witnessed 541 updates from 19 manufacturers, while 1,562 data sets were removed to reflect component obsolescence. By providing an updated library, Eplan ensures that designs and documents exported from the platform remain current and relevant.