In recent years, understanding the steps involved in wood furniture production has become increasingly vital for creating durable, high-quality pieces. Each phase of the process, from sourcing raw materials to the final packaging, plays a crucial role in ensuring the furniture meets industry standards and has a long lifespan. This guide outlines the comprehensive journey of wood furniture manufacturing, from logs to the finished product.

Sourcing the Logs

The production of wood furniture begins with logs, the primary raw material sourced from trees. Once harvested, these logs are transported to a sawmill for processing to prepare them for subsequent stages.

During the initial preparation, it’s essential to assess the logs based on tree species, size, and moisture content. At the sawmill, logs are examined and categorized according to their quality and type. Careful handling during this stage minimizes waste and damage, ensuring the wood remains suitable for future processing.

Sawmilling Operations

Sawmilling represents a significant step in the furniture-making process. Here, logs are cut into manageable panels and blocks based on specific size requirements. This allows for efficient drying in the next stages.

Initially, the wood is air-dried outdoors to allow excess moisture to evaporate before it undergoes kiln drying. Exposing the logs to ambient conditions for at least a week is crucial for proper preparation. Efficient sawmilling streamlines subsequent processes by organizing wood pieces by size and type, reducing the risk of damage during drying.

Kiln Drying

To ensure the wood is properly dried, kiln drying is performed to remove moisture. Achieving a moisture content of approximately 12–15% is vital to prevent issues like warping and cracking. This drying process can take between two to four weeks, influenced by the wood type, thickness, and drying conditions.

Both hardwood and softwood require effective kiln drying to maintain stability, especially softwoods that are prone to cracking if dried too quickly. Utilizing appropriate equipment is crucial in this phase to preserve the integrity of the wood, setting the stage for the next steps.

Cutting and Shaping

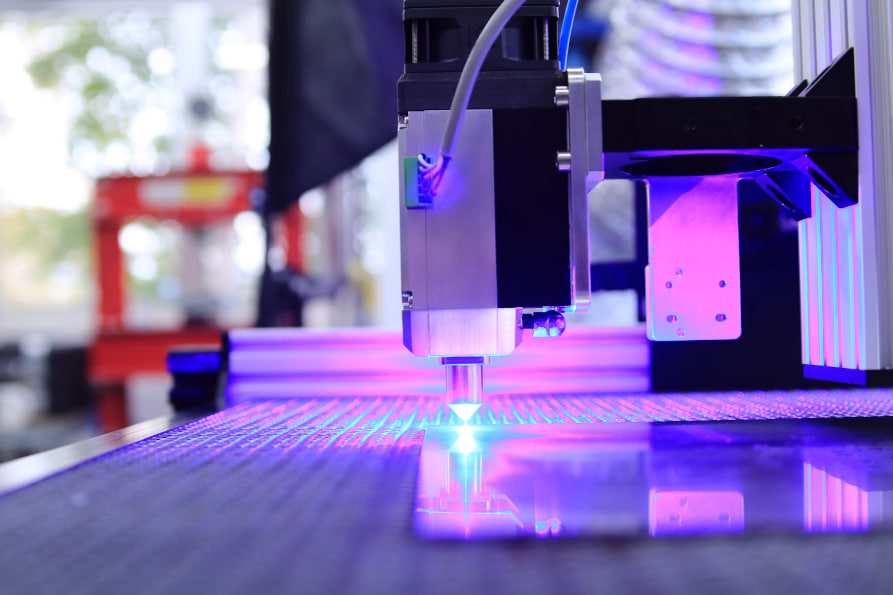

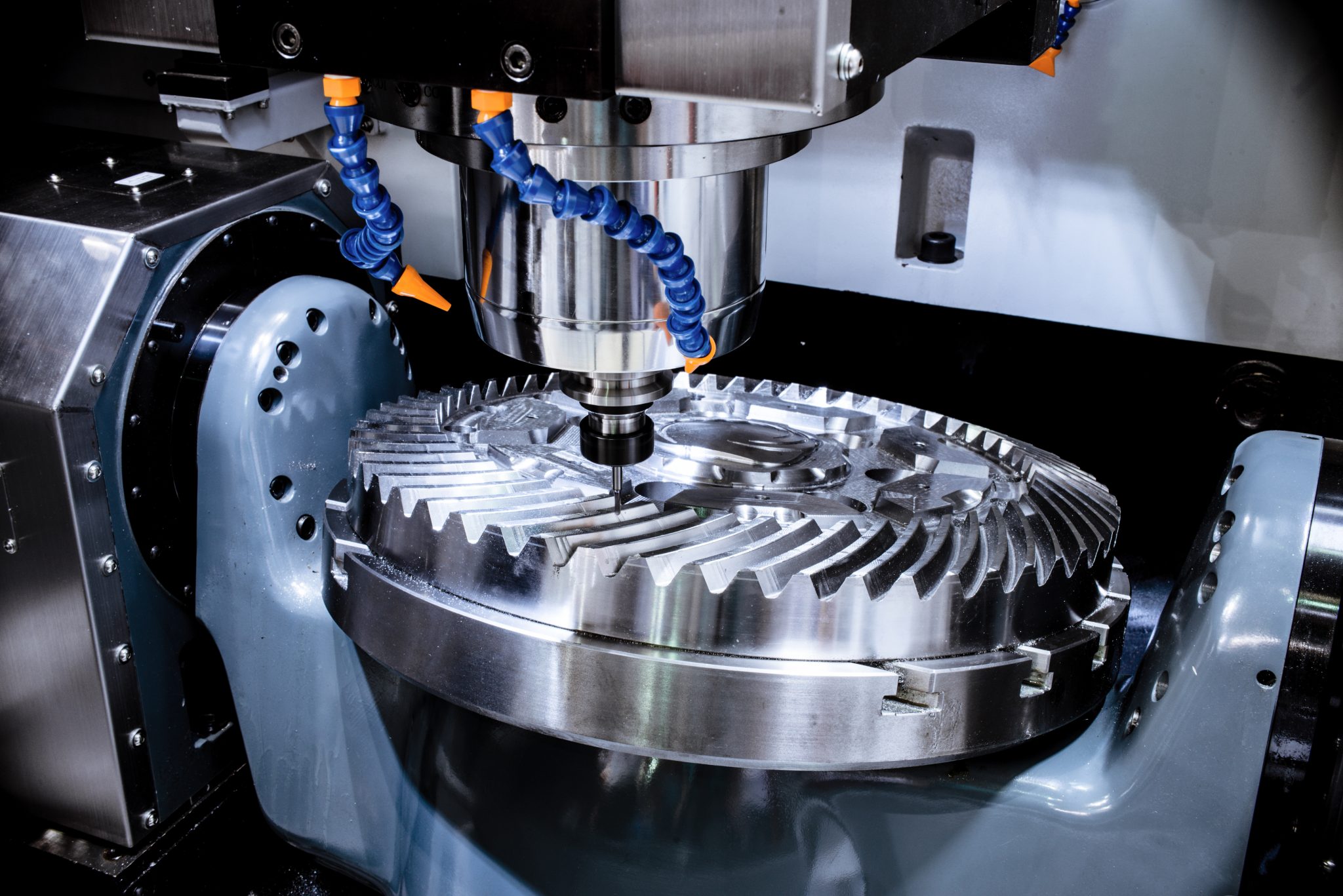

Once dried, the wood undergoes cutting and shaping. This involves using CNC machines or saw cutters to slice the wood into precise dimensions required for furniture pieces. Accuracy during this stage is essential to ensure all components fit seamlessly during assembly.

Effective cutting reduces waste and minimizes delays in the later stages. CNC technology is particularly beneficial, providing both precision and efficiency. Once cut, the components are ready for the next step: planing and drilling.

Planing and Drilling

In this phase, wooden components are processed through a planer to achieve a smooth, even surface. Proper planing is critical for preparing the pieces for subsequent work.

Following planing, the components are drilled using specialized tools to create accurate joints for assembly. This step is vital for ensuring the strength and durability of the final product. Additionally, thorough inspection of the pieces for defects is conducted to meet quality standards before they move on to sanding.

Sanding the Components

Sanding is a key process in refining the surfaces of all components before assembly. It ensures each piece is smooth and correctly sized, while also eliminating any minor imperfections that may have occurred during earlier stages.

Effective sanding enhances the quality of the finished product and prepares the wood for any coatings that may be applied later. Well-sanded furniture is also more resistant to wear over time, making it ready for assembly into the final product.

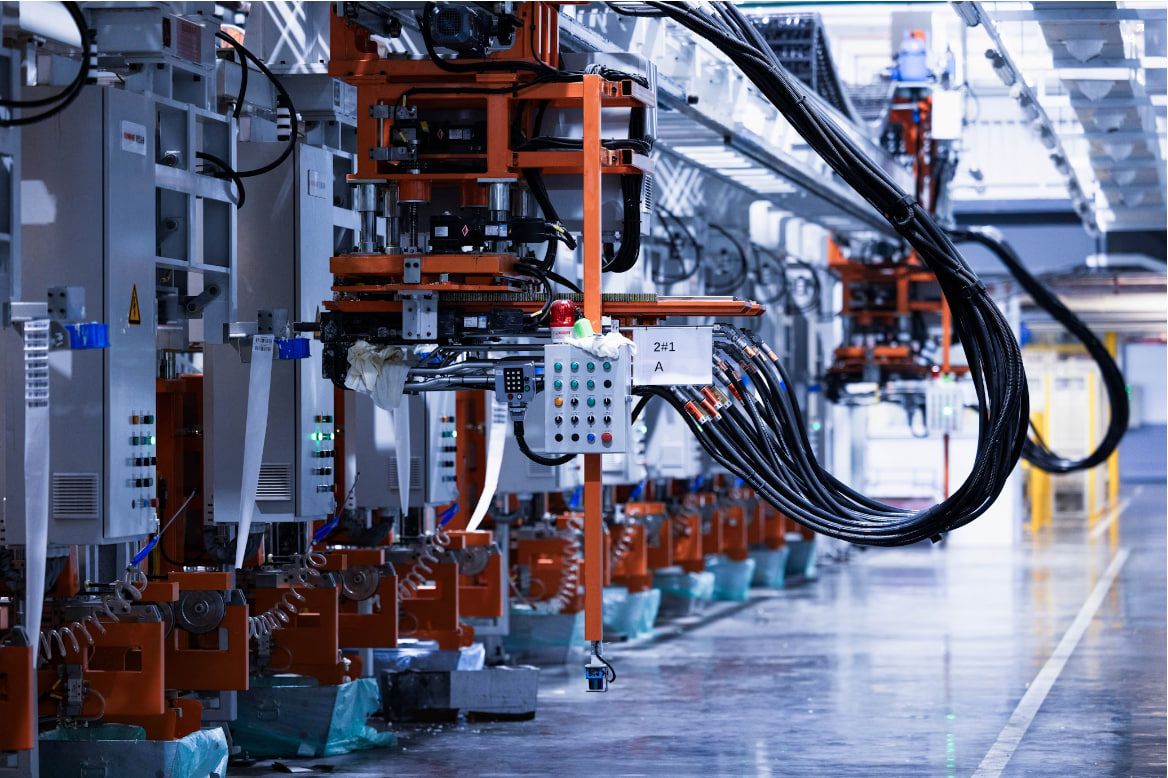

Assembling the Furniture

The assembly stage is critical in the furniture production process. This involves joining various components to create the final product. Depending on the design, some parts may be pre-assembled before finishing, while others are joined afterward.

This process demands precision and attention to detail to ensure that all pieces fit together correctly. The application of glue is essential for creating a solid, sturdy structure. Any imperfections in joints are addressed during assembly to maintain quality. While assembly may take time, it is integral to the durability and longevity of the furniture. After assembly, the product moves to the finishing stage.

Applying the Finish

Finishing provides the final touch to furniture, enhancing its aesthetic appeal and protecting it from damage. Coatings are applied to safeguard the wood from moisture and pests.

Whether finishing occurs before or after assembly depends on the type of furniture. Proper application ensures a long-lasting and attractive outcome. This stage also allows for customization, as various finishes can be used to achieve different looks. Once finished, the product is ready for packaging.

Packaging for Shipment

After finishing, furniture is transported to the packaging area, where it is prepared for delivery. Necessary accessories like handles, keys, or wheels are affixed as needed. Packaging methods vary based on product quality and destination.

High-end items or those shipped long distances require robust packaging to avoid damage during transit. Effective packaging is crucial for ensuring that the furniture arrives in perfect condition, upholding the manufacturer’s reputation. With the packaging complete, the wood furniture production process comes to a close.