OTT-JAKOB Spanntechnik, a German leader in tool clamping technology, has expanded its portfolio with the introduction of the Power-Check Micro—a compact device designed to assess clamping force in small-scale spindle interfaces. This newly developed tool caters to the needs of high-precision industries where space is limited and accuracy is critical.

Tailored for miniature spindles such as HSK E15, E16, and E20, the Power-Check Micro is intended for use in applications like dental technology, fine jewelry production, micro-component manufacturing, and sectors including aerospace and medical instrumentation. These industries depend heavily on stable, repeatable clamping performance due to the delicate nature of their machining tasks.

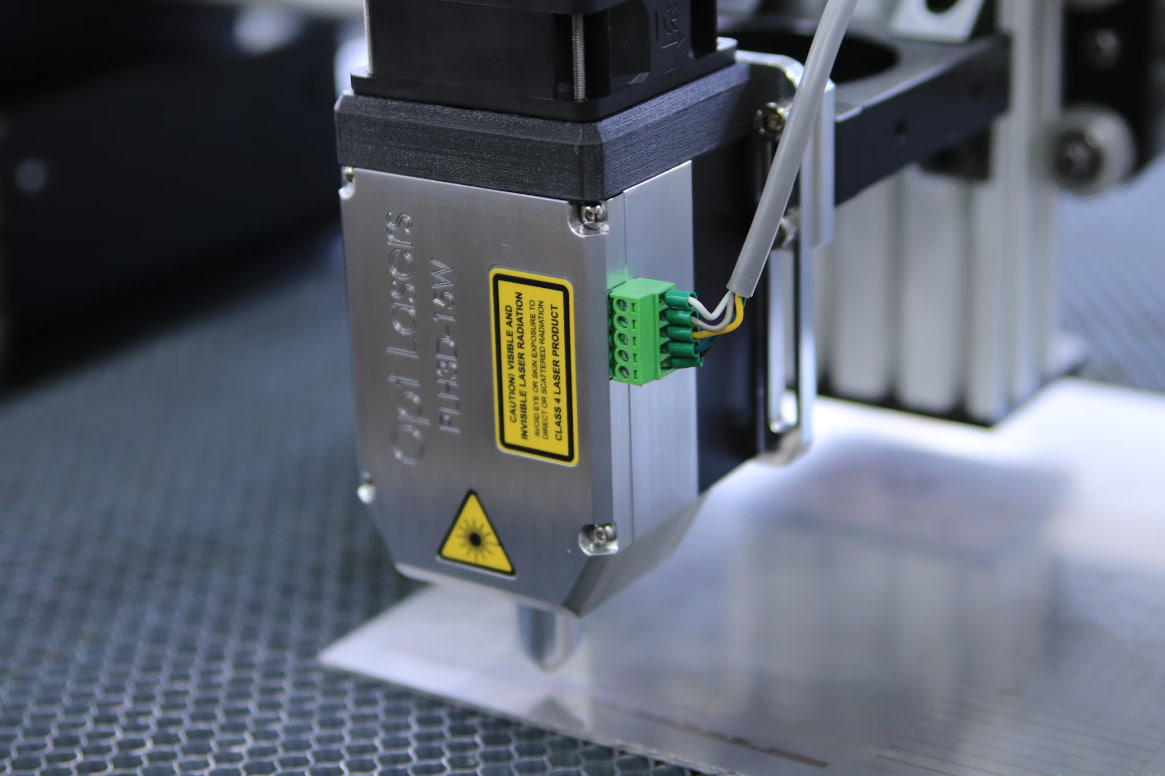

Distributed in the UK and Ireland through Gewefa UK, the Power-Check Micro is engineered to meet rising demands in miniature manufacturing for consistent monitoring and predictive maintenance. Unlike traditional measuring systems designed for large spindle formats like HSK 160, SK, or BT, this device fits seamlessly into smaller machine environments, thanks to its compact design—measuring just 48.8 x 43 x 41.5 mm and weighing approximately 200 grams.

The Power-Check Micro is battery-operated, eliminating the need for external power sources. Two replaceable lithium cells provide up to 1,000 hours of operation. Its wireless communication system transmits real-time data at a frequency of 2.4 GHz, with updates delivered once per second to a receiver. Integration is flexible, with USB and IO-Link modules available to support various digital workflows.

One of its standout features is the precision adjustment ring, which allows users to simulate deviations in tool holder size by increments of 0.05 mm, up to a ±0.2 mm range. This functionality enables more accurate replication of real-world tolerance variations—something rarely possible with static, nominal-only measurements.

The device supports interchangeable threaded adapters to suit different HSK interface sizes and is compatible with a broad range of tool clamping systems. Like its larger siblings in the Power-Check lineup, it measures axial drawbar force—ensuring that the retention mechanism holds the tool securely. A drop in clamping force may signal potential problems such as tool slippage, poor surface finish, or even catastrophic failure—risks that are unacceptable in high-precision machining.

Note that the Power-Check Micro is intended for manual insertion only and should not be used during automatic tool changes or while the spindle is running.

Users can purchase the device individually or as part of a comprehensive kit that includes software, a USB receiver, batteries, and a protective case. Routine calibration and scheduled testing are advised to keep measurements consistent and reliable.

With the Power-Check Micro, OTT-JAKOB continues to deliver advanced, user-friendly tools that help manufacturers uphold tight tolerances and maintain high standards—even at miniature scale.