As 2025 comes to an end, the CNC machinery industry stands at a pivotal point. This year has been marked by rapid technological evolution, growing automation, and a clear shift toward smarter, more sustainable manufacturing. From small workshops to large industrial plants, CNC systems have continued to redefine productivity and precision across multiple sectors.

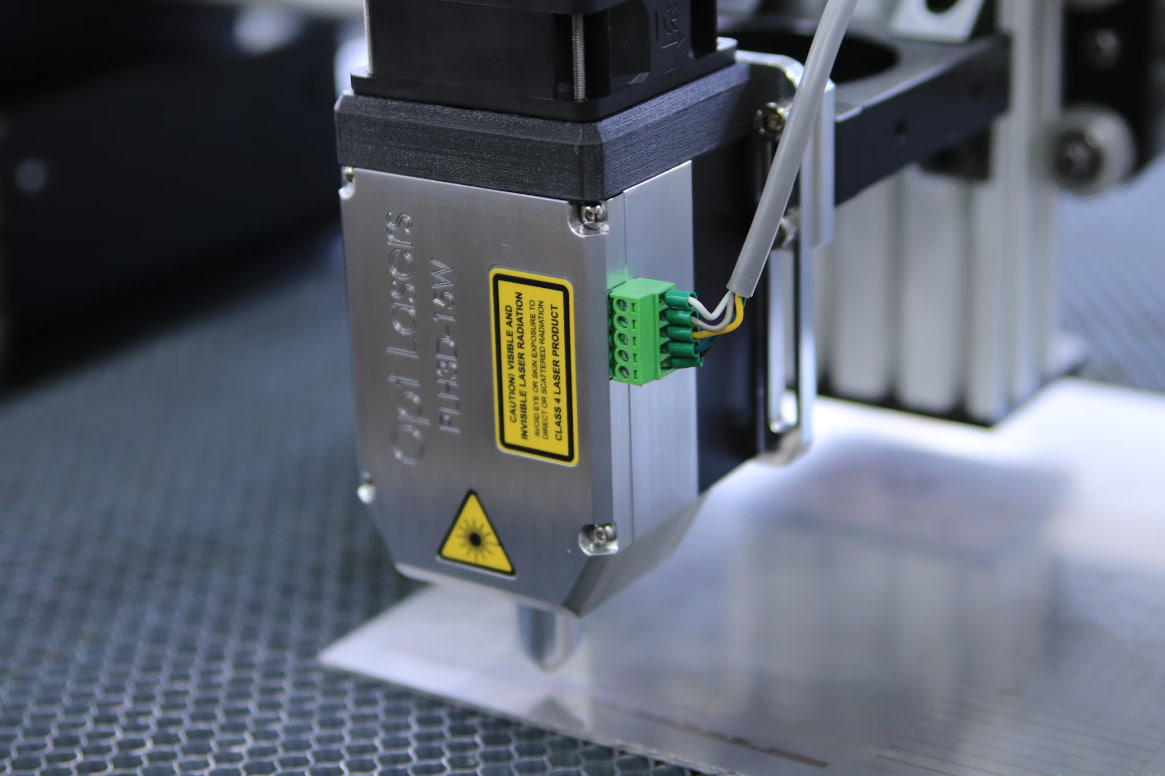

Smarter CNC Systems Powered by AI

One of the most notable developments in 2025 was the deeper integration of artificial intelligence into CNC machinery. AI-driven control systems are now widely used for predictive maintenance, tool wear detection, and adaptive machining. Instead of reacting to breakdowns, manufacturers increasingly rely on data analytics to prevent downtime before it occurs.

Modern CNC machines can automatically adjust cutting parameters in real time based on material behavior, vibration, and temperature. This has significantly improved surface quality, reduced scrap rates, and extended tool life.

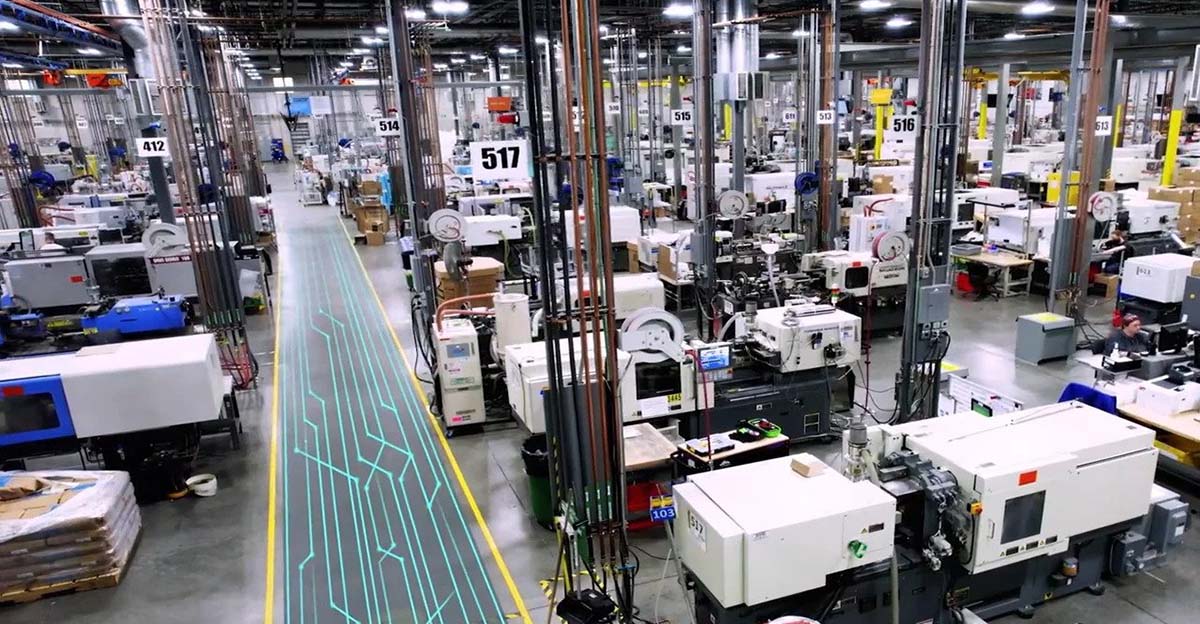

Automation and Lights-Out Manufacturing

Automation remained a dominant trend throughout 2025. Robotic arms, automated pallet changers, and integrated material handling systems have become standard components of many CNC installations. The concept of “lights-out manufacturing” — where machines operate unattended for long periods — is no longer limited to large corporations and is now accessible to mid-sized manufacturers.

This shift has helped companies address labor shortages while maintaining consistent output and high precision, especially in industries such as automotive, aerospace, and metal fabrication.

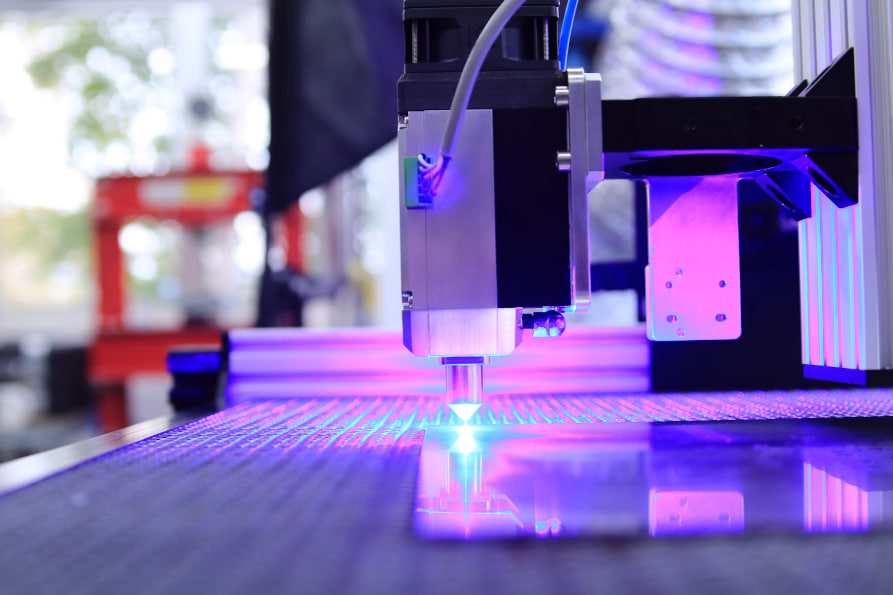

Growth of Multi-Axis and Hybrid Machines

Demand for multi-axis CNC machines continued to grow in 2025. Five-axis and even seven-axis systems are increasingly used to produce complex parts in a single setup, reducing lead times and improving accuracy.

At the same time, hybrid machines that combine CNC milling with additive manufacturing (3D printing) gained traction. These systems allow manufacturers to build up material and machine it precisely within the same workflow, opening new possibilities for prototyping and small-batch production.

Sustainability and Energy Efficiency

Environmental considerations played a larger role in CNC machinery development this year. Manufacturers focused on reducing energy consumption, optimizing coolant usage, and minimizing material waste. New spindle designs, energy-efficient drives, and smarter power management systems helped lower the overall environmental footprint of CNC operations.

Many companies also adopted dry or near-dry machining techniques, driven by both sustainability goals and rising energy costs.

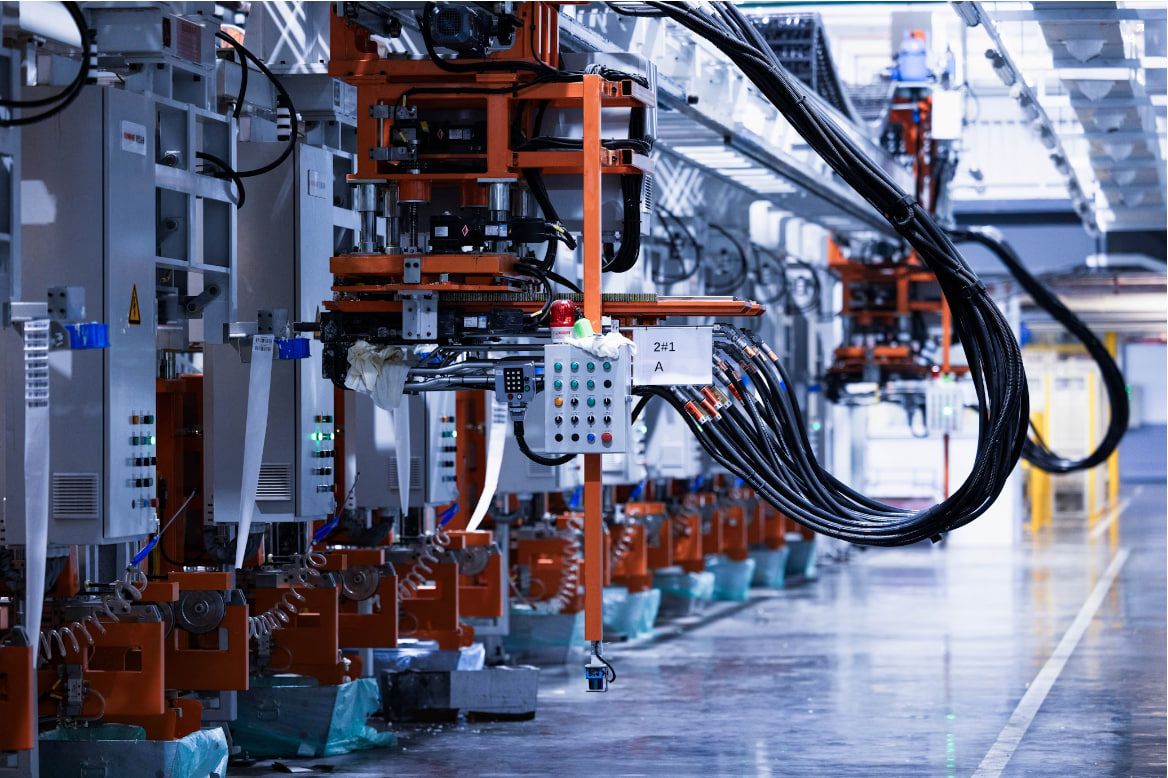

Software and Digital Integration

In 2025, CNC machines became more connected than ever. Advanced CAD/CAM software, cloud-based monitoring platforms, and digital twins are now tightly integrated with shop-floor equipment. This allows real-time performance tracking, remote diagnostics, and faster optimization of machining processes.

Cybersecurity also emerged as an important topic, as connected CNC systems require stronger protection against unauthorized access and data breaches.

Challenges and Outlook for 2026

Despite strong technological progress, the industry faced challenges in 2025. High equipment costs, supply chain fluctuations, and the need for skilled operators remain pressing issues. However, ongoing improvements in user-friendly interfaces and automation are helping lower the barrier to entry.

Looking ahead to 2026, the CNC machinery sector is expected to continue moving toward fully autonomous, digitally integrated, and sustainable manufacturing environments. Companies that invest in smart CNC solutions today will be best positioned to stay competitive in the years to come.