The metalworking industry is undergoing a transformative shift in 2024, driven by digital CNC machining, interconnected smart factories, and the emergence of the industrial metaverse. These advancements are redefining manufacturing processes, pushing companies to adopt user-friendly, adaptable technologies to remain competitive. Hakan Aydogdu, General Manager at Tezmaksan Robot Technologies, delves into these pivotal trends and their implications for manufacturers.

Driving Forces Behind Industry Growth

According to Deloitte, annual construction spending in manufacturing reached $201 billion by mid-2023—a 70% year-over-year surge. This momentum is expected to fuel further expansion in 2024, propelled by several key factors:

- Demand for Advanced Materials: Aerospace and automotive sectors are increasingly favoring lightweight, durable materials such as aluminum and titanium to boost energy efficiency.

- Electrification and Sustainability: Companies are investing heavily in green technologies, aligning with global decarbonization efforts.

- Innovation and Market Diversification: A report by Aptean highlights manufacturers’ focus on R&D and product development to attract new customers and explore untapped markets.

Key Technologies Shaping 2024

AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are reshaping the metalworking sector by enhancing precision and productivity. AI-driven design tools streamline the creation of complex components, while ML algorithms process extensive datasets to optimize decision-making.

Deloitte’s analysis reveals that 86% of executives see smart factories as a cornerstone of competitiveness within the next five years. These factories leverage AI, 5G, IoT, cloud computing, and data analytics to create integrated, efficient production environments. Examples include predictive maintenance powered by AI, IoT-enabled real-time monitoring, and seamless device communication facilitated by 5G networks.

The Rise of Digital Twins and the Industrial Metaverse

Once a concept limited to science fiction, digital twins now replicate real-world assets virtually, enabling manufacturers to simulate processes, equipment, and workflows for improved decision-making.

In 2024, digital twin technology is expected to merge with smart factory tools like IoT and cloud computing, creating expansive industrial metaverses. These virtual replicas of factories, machinery, and even cities will foster collaboration and connectivity on a global scale.

- Enhanced Collaboration: According to a study by Deloitte and MLC, 92% of manufacturers are experimenting with metaverse initiatives, which are anticipated to boost productivity, quality, and sales.

- Advanced Modelling: The integration of 3D scanning, immersive environments, and real-time data analytics will push the boundaries of simulation and optimization.

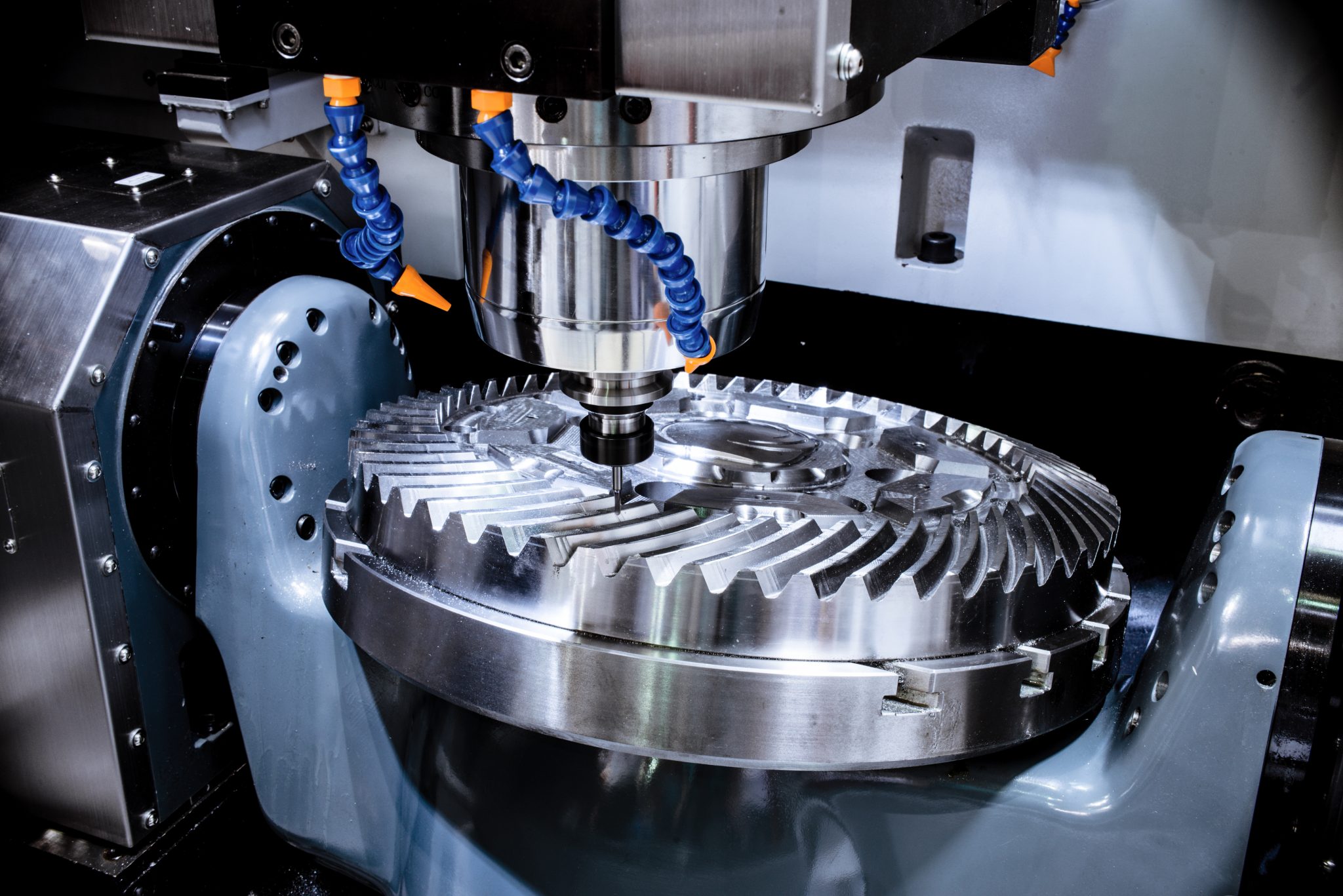

Automation and Interconnected Machinery

Automation continues to be a focal point in 2024, particularly in digital CNC machining. IoT sensors and generative AI tools are becoming integral to production lines, enabling streamlined processes and reduced manual intervention.

One standout innovation is the CubeBOX system, a robotic solution capable of running up to three CNC machines simultaneously. Its unique features include:

- 24/7 Operation: Continuous production without downtime during loading or unloading.

- Simplified Programming: The ROBOCAM software converts 2D CAD designs into CAM files, eliminating the need for complex coding skills.

- Flexibility and Adaptability: CubeBOX works with various CNC machines and control units, meeting diverse manufacturing needs.

By reducing operator involvement and maximizing output, CubeBOX exemplifies the future of lean, automated production.

Preparing for the Future

To stay ahead in 2024’s rapidly evolving industrial landscape, manufacturers must embrace transformative technologies and innovative approaches. Concepts like AI-driven automation and the industrial metaverse, once considered futuristic, are now essential tools for success. By integrating these advancements with Industry 4.0 principles, businesses can not only meet the challenges of tomorrow but also thrive in a competitive, interconnected world.