Five-axis CNC milling technology is available in two main configurations: vertical machining centers (VMCs) and horizontal machining centers (HMCs). Choosing the right one can significantly influence precision, efficiency, and overall production costs. Below is a breakdown of how these two setups differ in operation, advantages, and limitations.

Vertical 5-Axis Machining

In a vertical machining setup, the spindle approaches the workpiece from above, moving along the z-axis. Rotational movement is typically provided by trunnion-style tables, which allow two additional axes of flexibility.

Advantages of VMCs:

- Compact tool setups: Because vertical machines often feature smaller spindles, operators can use shorter tools, which improves rigidity, extends tool life, and enhances surface quality.

- Clear visibility: The open structure of a VMC allows operators to directly monitor machining progress, making troubleshooting easier.

- Ease of use: Since vertical 5-axis systems are widely used, operators usually adapt quickly, reducing training time.

- Lower upfront cost: VMCs are typically more affordable than horizontal units, lowering the financial barrier for workshops.

- Space efficiency: Their relatively small footprint makes them easier to integrate into existing production floors.

- High precision: Ideal for jobs requiring intricate details, such as tool and die manufacturing.

Challenges with VMCs:

- Setup interruptions: Parts cannot usually be swapped while machining is in progress, which may slow down throughput unless automation is added.

- Chip management issues: Material chips often accumulate around the workpiece, potentially affecting tool wear and finish quality.

Horizontal 5-Axis Machining

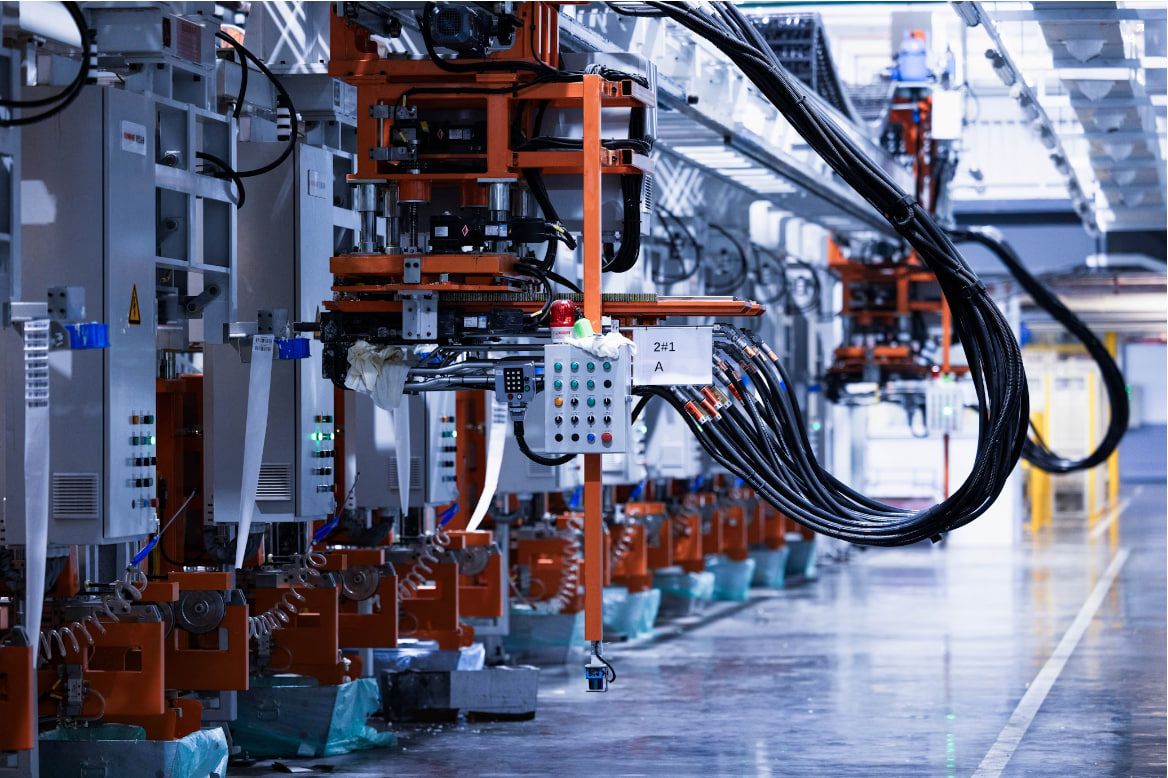

With horizontal machines, the spindle runs parallel to the ground and moves along the y- and z-axes. These machines are often chosen for large-scale or heavy-duty milling where material removal rates are high.

Advantages of HMCs:

- Efficient chip evacuation: Gravity naturally assists in clearing chips and coolant, which improves part quality and reduces tool wear.

- Higher productivity: Thanks to rotating tables, new parts can be loaded while others are being machined, minimizing downtime.

- Operational flexibility: Some HMCs allow entire milling heads to be swapped, enabling multiple processes within one setup.

- Reduced labor input: Continuous operation with minimal idle time helps lower staffing costs over the long run.

Challenges with HMCs:

- Space requirements: HMCs occupy more floor area, though this often comes with increased production capability.

- Higher investment: The robust construction and larger design make them considerably more expensive than VMCs.

Which One to Choose?

The decision largely depends on the type of work being done. Vertical 5-axis machines are well-suited for smaller, highly detailed parts and offer a cost-effective entry point for precision machining. Horizontal systems, on the other hand, excel at large, heavy parts and continuous high-volume runs, making them better suited for industrial-scale operations.

Both machine types can be enhanced with automation solutions, enabling manufacturers to maximize spindle time and efficiency regardless of configuration.