This week marked a significant moment in industrial manufacturing as industry experts visited Picanol’s state-of-the-art facility in Belgium. The weaving machine manufacturer, renowned for its global leadership in textile technology, recently celebrated an extraordinary achievement – the sale of its 400,000th weaving machine worldwide, cementing its position as an industry pioneer.

Revolutionizing Textile Manufacturing Through Innovation

Picanol’s success stems from its relentless pursuit of manufacturing excellence. The company has implemented groundbreaking production strategies that significantly reduce assembly times while maintaining exceptional quality standards. A key component of this strategy involves their strategic partnership with IBARMIA, a leader in precision machining technology, and their local partner Geroud.

Next-Generation Manufacturing Solutions

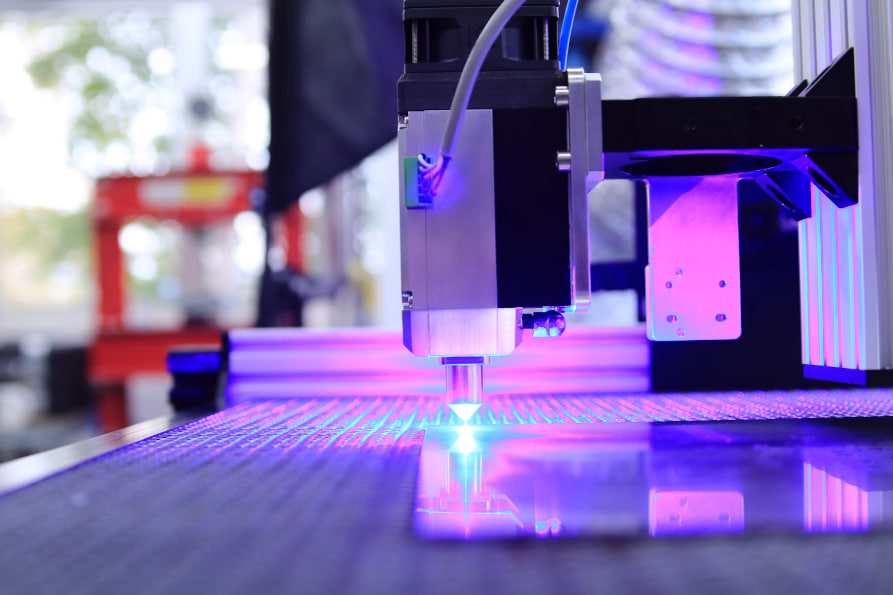

The centerpiece of Picanol’s technological advancement is a revolutionary IBARMIA machining system featuring:

- An innovative moving column design

- An expansive 8-meter X-axis capacity

- Dual-spindle configuration

- Integrated robotic automation

This comprehensive manufacturing solution represents a quantum leap in production efficiency. The system’s intelligent design enables simultaneous machining operations, dramatically increasing output while maintaining Picanol’s renowned precision standards. The automation components significantly reduce manual intervention, minimizing production interruptions and enhancing overall equipment effectiveness.

Engineering the Future of Textile Manufacturing

Picanol’s investment in this advanced manufacturing technology demonstrates their commitment to maintaining industry leadership. The IBARMIA integration provides:

- Enhanced production capacity to meet global demand

- Improved machining accuracy for superior product quality

- Optimized workflow efficiency through intelligent automation

This strategic equipment selection reflects Picanol’s forward-thinking approach to manufacturing. By combining precision engineering with smart automation, the company continues to set new benchmarks in weaving machine production, ensuring they can deliver their industry-leading solutions to customers worldwide with unmatched efficiency and reliability.

The successful implementation of this advanced manufacturing system underscores Picanol’s dedication to technological innovation as they continue to shape the future of textile production on a global scale.