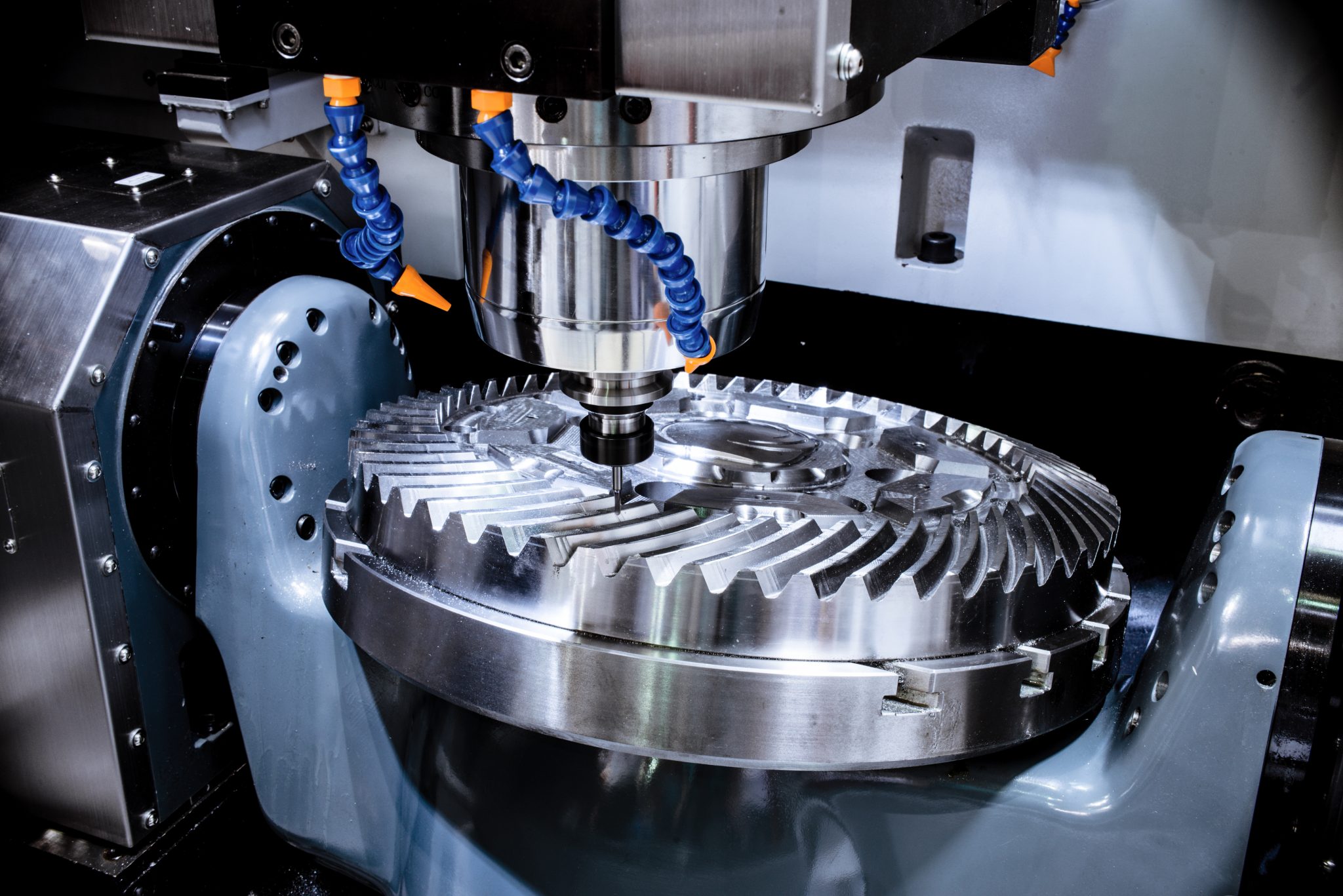

In high-speed CNC operations, especially when working with complex designs or durable materials like titanium or carbon fiber, vibration presents a major challenge. Chatter — the term for unstable contact between the tool and material — not only degrades surface quality but also leads to premature tool wear and possible machine damage. Standard approaches, such as passive dampers or static control algorithms, often prove ineffective when machining parameters shift mid-process.

In fields like aerospace, medical manufacturing, and high-performance automotive production, where tolerance levels are measured in microns, inconsistent vibration control can translate into wasted resources, extended production cycles, and increased expenses.

Smarter CNC Control: Machines That Adapt and Learn in Real Time

The latest generation of CNC controllers leverages machine learning and real-time sensor feedback to combat vibration intelligently. These systems don’t just follow pre-programmed instructions—they interpret machining conditions on the fly and respond instantly. Through integration with smart sensors and advanced data processing, they continuously update their behavior to eliminate chatter before it disrupts production.

Core Benefits of Intelligent CNC Systems

1. Instantaneous Parameter Optimization

Unlike conventional machines that run on static setups, AI-enhanced controllers adjust variables such as spindle speed, feed rate, and tool path in real time, reacting to material changes, tool condition, or heat buildup—without operator input.

2. Vibration Control Before It Begins

Sensor arrays—including force sensors and accelerometers—monitor vibrations at the earliest onset. Predictive software models identify patterns and suppress chatter before it becomes problematic, ensuring process stability from start to finish.

3. Improved Tool Longevity and Part Accuracy

Reducing mechanical stress means longer tool life and fewer replacements. Consistently smooth cuts also mean more accurate parts, with less scrap and rework.

4. Compatibility with Existing Infrastructure

Many of these advanced controllers are designed to retrofit into current CNC setups. Additionally, cloud synchronization allows shared learning across a network of machines, making upgrades scalable.

Under the Hood: What Powers These Smart Systems?

AI and Predictive Analytics

Modern control platforms use neural networks trained on thousands of machining datasets. They identify cause-and-effect relationships—between spindle dynamics, vibration signatures, and tool deflection—and apply that knowledge to improve every cut.

Integrated Sensor Systems

- Accelerometers pick up micro-vibrations.

- Force sensors gauge tool resistance in real time.

- Acoustic emission sensors detect tool wear before it affects part quality.

Combining these feeds creates a detailed picture of the machining process, allowing microsecond-level corrections that outperform any human operator.

On-Board Processing with Edge Computing

Edge computing allows these systems to process data locally, right on the machine. This eliminates the lag of cloud-based solutions, ensuring immediate reaction during high-speed operations.