Proto Labs has committed €4 million to enhance its European infrastructure, marking its most significant investment since the establishment of its UK division in 2005.

This substantial investment will fund the acquisition of state-of-the-art manufacturing technology and facility upgrades, primarily centered in Telford, UK, but extending to other European locations. The decision to invest comes as Proto Labs strategically positions itself to meet the current and anticipated demand for its advanced manufacturing services across Europe.

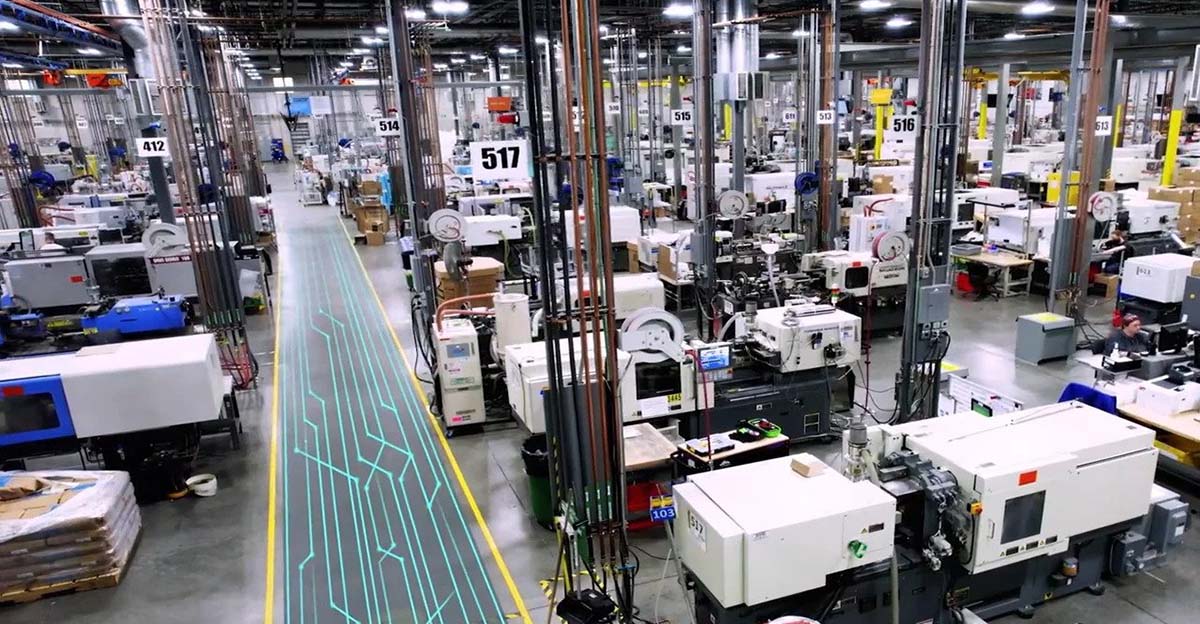

In June and July of 2017, Proto Labs, a leading provider of digital manufacturing services encompassing 3D printing, CNC machining, and injection molding, finalized large-scale acquisitions of Haas CNC machines and ARBURG injection molding machines. The Haas machines will be configured for either mold making or component machining, bolstering services experiencing rapid growth. With these new additions, Proto Labs UK now boasts an inventory of 130 CNC machining and 57 injection molding machines.

Lee Ball, General Manager of Proto Labs UK, highlighted the company’s commitment to providing fast and reliable service to customers across diverse industries, emphasizing the importance of quick turnaround in product development. Ball stated, “Our continuous investment enables us to meet the evolving needs of our extensive customer base.”

The demand for molded parts is steadily increasing across various sectors, prompting Proto Labs to invest in new technology to accommodate projected growth. Similarly, Proto Labs’ industrial 3D printing service, operating from two sites in Germany, is witnessing heightened demand.

Daniel Cohn, Managing Director of Proto Labs’ 3D printing business in Feldkirchen, Germany, noted the surge in order intake driven by customers from diverse industries, recognizing the cost-effective prototyping opportunities offered by 3D printing technology, particularly for parts with complex geometries.

The company’s recent capacity expansion aligns with its overall business growth in Europe, with manufacturing, engineering, sales, and administrative functions experiencing annual growth rates exceeding 20% since 2015.

Lee Ball emphasized the need for additional space within the next 18 to 24 months to accommodate anticipated growth, both in office space and manufacturing capacity. Similar expansion plans are underway for Proto Labs’ German facilities in Eschenlohe and Feldkirchen to support expected growth.