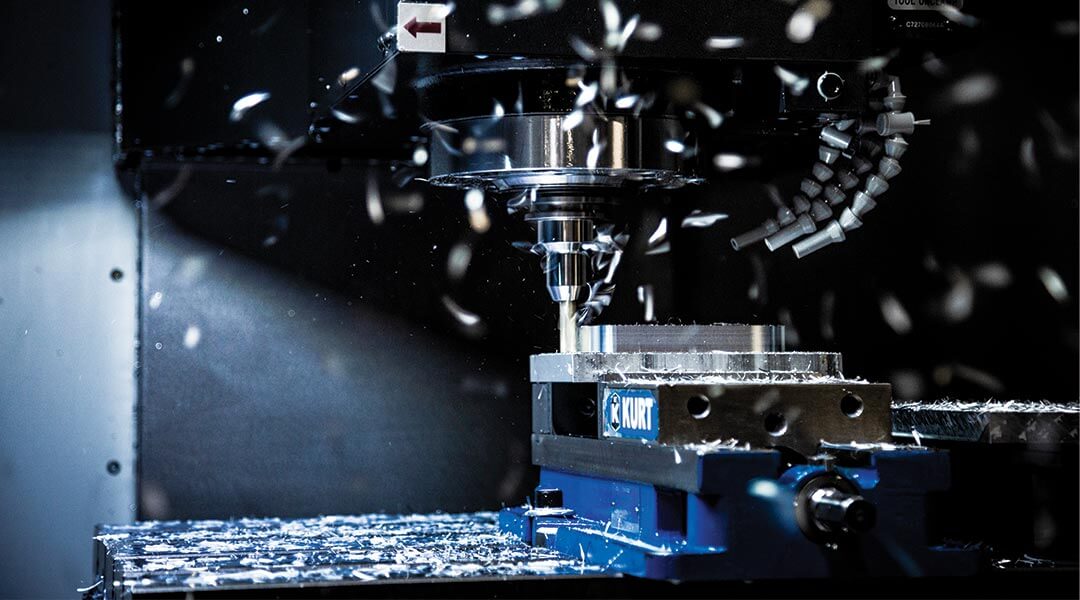

The incorporation of the fourth axis in CNC machining centers involves the integration of a CNC dividing head, commonly referred to as the fourth axis. The presence of this additional axis, which is essentially a CNC dividing head, has significantly enhanced the machining efficiency of machining centers while concurrently reducing costs. The application of the fourth axis is essential in the processing of numerous products.

The fourth axis of CNC machining centers plays a pivotal role in tasks that are beyond the capability of a three-axis machine tool. Through controlled rotation, it enables multi-faceted processing, substantially improving processing efficiency and minimizing the need for frequent clamping, especially in the machining of cylindrical parts.

- Simultaneous Processing of Multiple Surfaces: The rotation angle facilitated by the fourth axis allows for the simultaneous processing of multiple surfaces. This not only enhances the overall processing accuracy of the workpiece but also streamlines the manufacturing process, leading to improved production efficiency and reduced production time.

- Tool and Workpiece Angle Offset: While the three linear moving coordinates (XYZ) represent the three axes, the fourth axis is typically a rotating axis. This rotational capability introduces an angle offset between the tool and the workpiece. This angle, formed between the tool axis and the workpiece surface normal, serves two main purposes. First, it broadens the machining range, and second, it optimizes cutting conditions.

The integration of the fourth axis in production and processing has significant advantages. It expands the possibilities for NC blade production and processing plans, elevating the production and processing standards. Moreover, it minimizes the need for equipment adjustments during the production process, thereby enhancing work efficiency and simplifying the overall production process.

The fourth axis introduces flexibility in laser cutting for production and processing applications. With the ability to adjust the distance and angle of view between the workpiece and the laser cutting tool, it automatically generates optimal working plans. This adaptability ensures a superior actual effect of laser cutting, providing enhanced precision and versatility in the manufacturing process.