Medical tools, instruments, and paraphernalia are evolving rapidly, with new tech innovations enhancing patient care and overall well-being. Such items can be found in various settings, from operating rooms to therapy facilities and from rural health centers to home first aid kits.

Though these medical items differ in purpose, they exhibit several universal characteristics:

- Foremost, their construction should ensure the utmost safety, including the materials from which they are crafted.

- They should function consistently, maintaining specific standards for repetitive and predictable outcomes.

- Many are tailored to fit particular needs, especially related to the human body’s unique intricacies.

- It’s vital that new inventions transition smoothly from concept to market launch after thorough testing and validation.

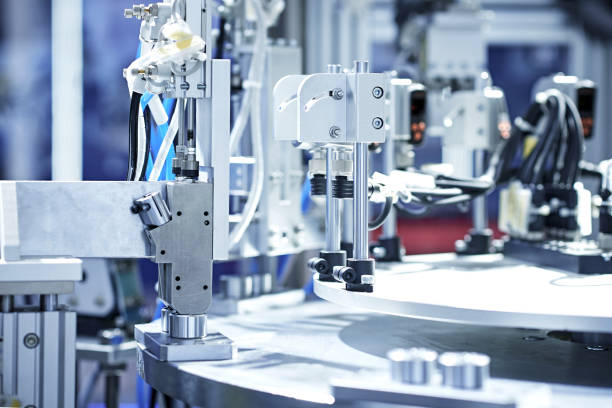

CNC (Computer Numerical Control) manufacturing has emerged as a perfect solution, addressing these needs effectively.

Modern Innovations in CNC Production

The ongoing evolution in CNC tooling technology is a response to market needs. As designs become more intricate, the demand for heightened precision grows, pushing the boundaries of tool design possibilities.

Manufacturers continuously strive to enhance equipment performance. Their goals include managing vibrations, boosting machine velocity, curtailing upkeep expenses, and delivering adaptable machining setups capable of multifaceted tasks in a single operation.

There are three cutting-edge technical advancements aiding in these pursuits:

1. Magnetic Linear Drives: Traditional multi-axis CNC devices maneuver along several independent pathways, usually via a linear screw drive mechanism. These methods often suffer from friction, wear, and limited speed and accuracy. However, magnetic linear drives operate similarly to Maglev trains. Magnetic forces lift the carriage from its track and also propel its movement, minimizing friction, wear, and the need for maintenance. This approach achieves superior speed and precision.

2. Oil-Cushioned Guides: To reduce friction, another ingenious technique involves oil-cushioned guides. These guides use an oil film, consistently pumped, to minimize friction and vibration, ensuring remarkable finished product quality.

3. Thermal Regulation: During high-performance machining, heat accumulation can challenge precision due to material expansion. To counteract this, advanced cooling mechanisms are employed, and adept manufacturers can anticipate and adjust for such thermal expansions.

Given its attributes, CNC machining stands unmatched in reliability, accuracy, affordability, adaptability, and scalability. Let’s delve into how CNC production particularly benefits medical device development in pivotal aspects.

Swift Prototyping: Prototypes are foundational for all new inventions. With CNC, once a design is greenlit, actual parts can materialize within a day. This swift turnaround accelerates crucial prototype evaluations.

Accuracy and Consistency: Advanced CNC equipment can replicate designs with microscopic variances, ensuring unmatched precision. Previously, such accuracy was reserved for expert machinists in controlled conditions, but now digital innovations have made perfection commonplace.

Flexible Production: Unlike other manufacturing techniques that necessitate costly and time-consuming molds or casts, CNC doesn’t mandate such investments. This flexibility ensures cost-effective production, even in limited quantities.

Material Versatility: CNC machinery is adaptable, processing varied raw materials with minor adjustments. This allows designers and medical professionals significant flexibility in material selection.

Regulatory Compliances: Essential certifications, such as ISO 13485, guarantee that manufacturers uphold stringent quality standards throughout the production process. It’s essential to emphasize that regulatory clearances, like FDA approvals, lie with the product’s designer or owner, not the manufacturer.

Diverse Applications: CNC’s adaptability allows it to cater to numerous customized medical product fabrications, from surgical tools to testing equipment components. However, for large-scale plastic components, injection molding is more appropriate.