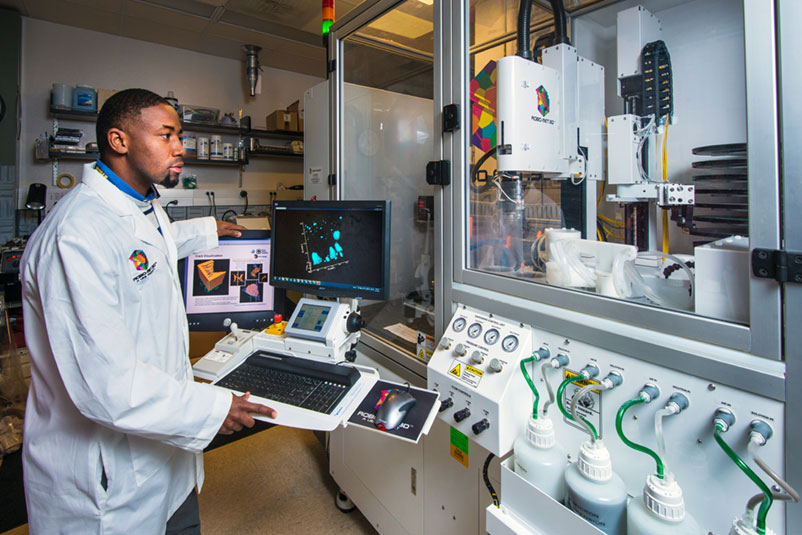

CNC equipment is a cornerstone in numerous production and manufacturing workflows. These devices have the prowess to undertake intricate operations with unparalleled precision, rendering them indispensable to many sectors. Yet, as with any technological apparatus, CNC devices necessitate periodic upkeep to guarantee optimal performance. This article sheds light on the significance of consistent maintenance of CNC equipment and its implications for the machine’s durability and productivity.

Consistent upkeep of CNC equipment mitigates the risks of expensive malfunctions and operational halts. Through timely maintenance, potential glitches can be pinpointed and rectified before escalating into substantial challenges. In the bigger picture, proactive measures tend to be more economical than reactive solutions, as the latter might involve costly repairs or replacements. Moreover, such timely care can prolong your CNC equipment’s lifespan, maximizing the value derived from your capital expenditure.

The fidelity and precision of your equipment can also be enhanced with periodic maintenance. As devices function over time, certain components might deteriorate or accumulate dirt, compromising their efficiency. By ensuring machines are consistently in prime condition, the quality and precision of the outputs can be fortified. This precision is paramount for sectors demanding stringent specifications, like aviation or biomedicine.

Another salient advantage of maintenance is bolstering the safety of CNC equipment. Aging equipment can manifest signs of wear and tear, escalating the probability of mishaps and related hazards. A steadfast maintenance routine safeguards against these risks, ensuring machines remain safe for use. Furthermore, adhering to routine checks can ascertain compliance with safety norms, safeguarding you from potential legal repercussions.

Elevating the productivity of your CNC equipment is yet another benefit of maintenance. Ensuring that devices are always in top-notch condition can amplify output rates and diminish operational interruptions. It’s also worth noting that maintenance can bolster the machine’s energy efficiency, translating to more sustainable operations and slashed energy expenses.

It’s pivotal, when embarking on CNC equipment maintenance, to abide by the stipulations set by the machine’s manufacturer. This ensures the machine receives the right care, using apt components and methods. Furthermore, meticulous record-keeping of all maintenance activities can serve as a valuable reference to monitor equipment health and preempt significant issues.

To wrap up, the consistent upkeep of CNC equipment is cardinal to ensure the machine’s operational longevity and peak performance. By championing maintenance, businesses can avert expensive halts, elevate output precision, ensure operational safety, and enhance machine efficiency. Adhering to the manufacturer’s advice and meticulous record-keeping further refines the process. Embracing these strategies ensures CNC equipment continues to offer substantial value for its cost.