CNC machining has been a game-changer in the manufacturing industry, revolutionizing the way products are made with high precision and accuracy. The medical industry has not been left behind in this revolution as CNC machining is changing the way medical devices and implants are manufactured. This article discusses how CNC machining is transforming the medical industry and the benefits that come with it.

Customization

One of the most significant advantages of CNC machining in the medical industry is the ability to customize medical devices and implants. CNC machining allows for the production of highly customized medical devices that can be tailored to fit a patient’s specific needs. This level of customization is critical in cases where a patient has a unique medical condition that requires a specialized device or implant.

For example, in dental implantology, the use of CNC machining has enabled dentists to produce implants that are customized to fit a patient’s unique jawbone structure, resulting in improved patient outcomes. The ability to produce customized implants is also vital in orthopedic surgery, where implants need to fit precisely to minimize the risk of complications.

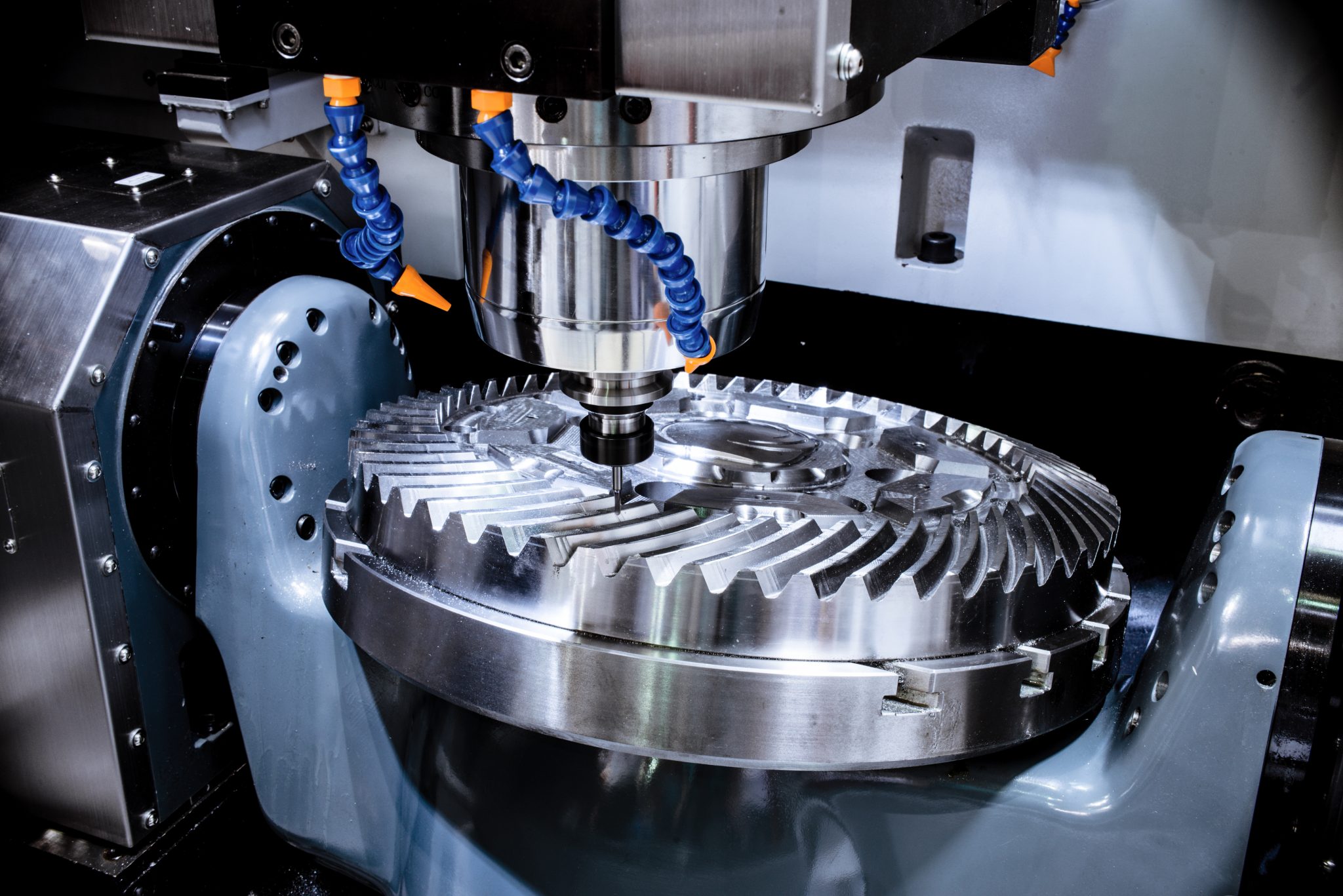

Accuracy and Precision

CNC machining is renowned for its high level of accuracy and precision, and this is critical in the medical industry where the stakes are high. With CNC machining, medical devices and implants are produced with unmatched precision, ensuring that they meet the strict quality and safety standards.

The use of CNC machining in the production of surgical instruments, for instance, has led to the production of tools with precise geometries and tolerances, ensuring that they perform their intended function optimally. Similarly, in orthopedic surgery, CNC machining has made it possible to produce implants that fit perfectly into the patient’s bone structure, resulting in reduced risk of complications and improved patient outcomes.

Speed and Efficiency

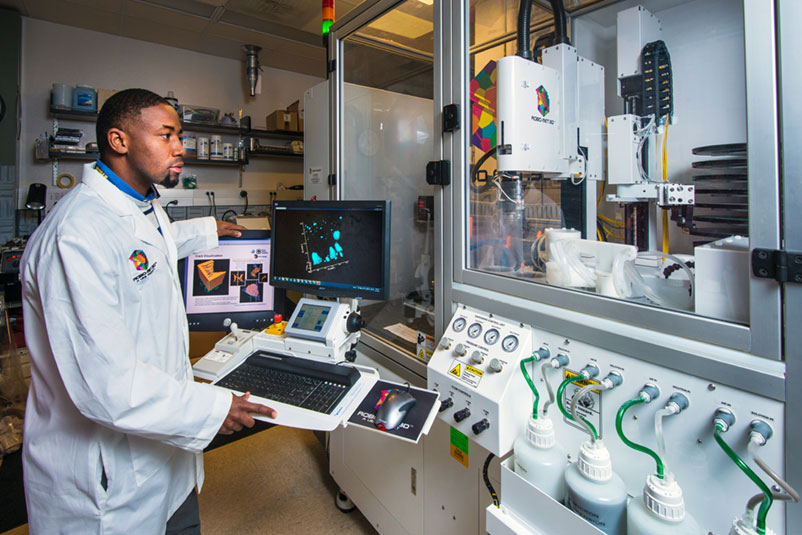

Another significant advantage of CNC machining in the medical industry is the speed and efficiency it offers in the production of medical devices and implants. CNC machines operate at high speeds and can produce medical devices and implants in large quantities in a short time.

This level of speed and efficiency is critical in emergency situations, where the need for medical devices and implants is urgent. CNC machining has made it possible to produce devices and implants quickly and efficiently, ensuring that they are readily available when needed. This has significantly improved patient outcomes and reduced the waiting time for patients.

Cost-effectiveness

CNC machining is a cost-effective manufacturing process that has significantly reduced the cost of producing medical devices and implants. The level of automation offered by CNC machining reduces the need for manual labor, which minimizes the cost of production.

This cost-effectiveness has made it possible to produce high-quality medical devices and implants at an affordable cost, making them accessible to more patients. CNC machining has made it possible to produce complex orthopedic implants at a lower cost than traditional casting methods, making them more affordable to patients.

Innovation

CNC machining has opened up new possibilities in the medical industry by enabling the production of highly complex medical devices and implants that were previously impossible to manufacture. The ability to produce highly customized devices and implants has led to the development of new treatment options for various medical conditions.

For example, CNC machining has enabled the production of patient-specific implants for the treatment of spinal injuries, resulting in improved patient outcomes. Similarly, CNC machining has made it possible to produce customized prosthetic limbs that match the unique anatomy and functional requirements of the patient.

Conclusion

CNC machining is changing the medical industry, and the benefits are immense. From customization to accuracy, speed, cost-effectiveness, and innovation, CNC machining has transformed the way medical devices and implants are produced. The use of CNC machining has led to improved patient outcomes and has made medical devices and implants more accessible to patients. As technology continues to advance, it is exciting to see the new possibilities that CNC machining will bring to the medical industry