Mitsubishi Electric Automation introduces iQ Care Remote4U for CNC customers.

Mitsubishi Electric Corporation recently introduced its iQ Care Remote4U Service. The service provides a way for the company’s CNC customers to get their machine tools up-and-running.

iQ Care Remote4U

With this new remote solution, operations may run more smoothly with reduced hindrance from unnecessary, drawn-out downtime. The iQ Care Remote4U platform has been designed to offer a birds-eye view of production that can be accessed and utilized remotely.

Mitsubishi’s remote maintenance solution allows its field service engineers to simultaneously analyze a customer’s CNC machine parameters and alarm history in real-time while troubleshooting errors or issues stopping its proper functioning.

The service enables the confirmation of system faults or signs of any faults and can estimate machining time in real-time through its Remote Diagnosis Function.

A mobile terminal, such as a computer, can make use of this. Rapid support through remote diagnosis is made possible through a connection from a terminal installed in a service center to a customer’s machine.

The iQ Care Remote4U service utilizes the Dashboard Function to collect, compile, and perform central management and operating/cost information from many units. This helps customers improve their production processes and reduce operating costs through visualization-based analysis.

In a recent news release, Services Product Manager at Mitsubishi Electric Automation, Adam Gatza, commented, “iQ Care Remote4U gives our customers and engineers a platform to view problems simultaneously giving both parties more confidence in diagnosing the problem in a shorter timeframe and start putting together an action plan on how to fix it.”

Additional Control Solutions

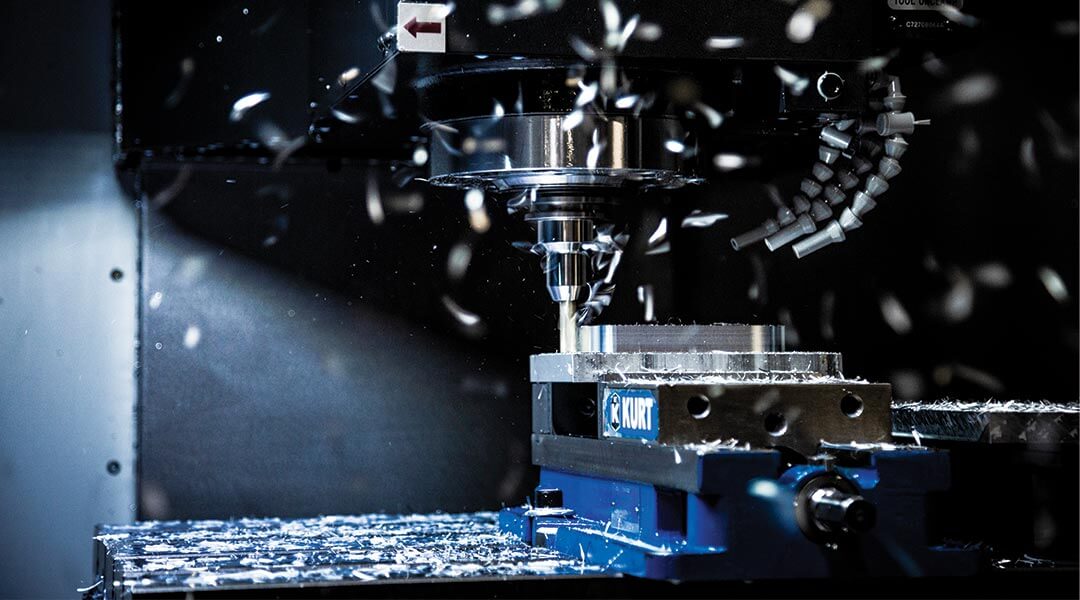

Mitsubishi has various other CNC machining solutions available to its customers. This includes high-speed/high accuracy machining functions (tool center point control, high-speed, and high accuracy control).

It also includes compensation functions (rotation sensor error compensation, tolerance control, workpiece installation error compensation), IoT functions (MES interface, solution for intelligence), and others.

Mitsubishi’s Direct Robot Control Function

This function enables robot-friendly CNC control. Users can control and automate Mitsubishi and KUKA robots using G-code by themselves. The Direct Robot Control Function also provides users with a uniform coordinate system for robots and machine tools.

Additionally, Mitsubishi offers its CNC M800/M80 Series manufacturing execution system (MES) interface function, enabling CNC machining information and machine tool operation status to be sent to MES.

Mitsubishi hopes this new iQCare Remote system will help users with their CNC operations.